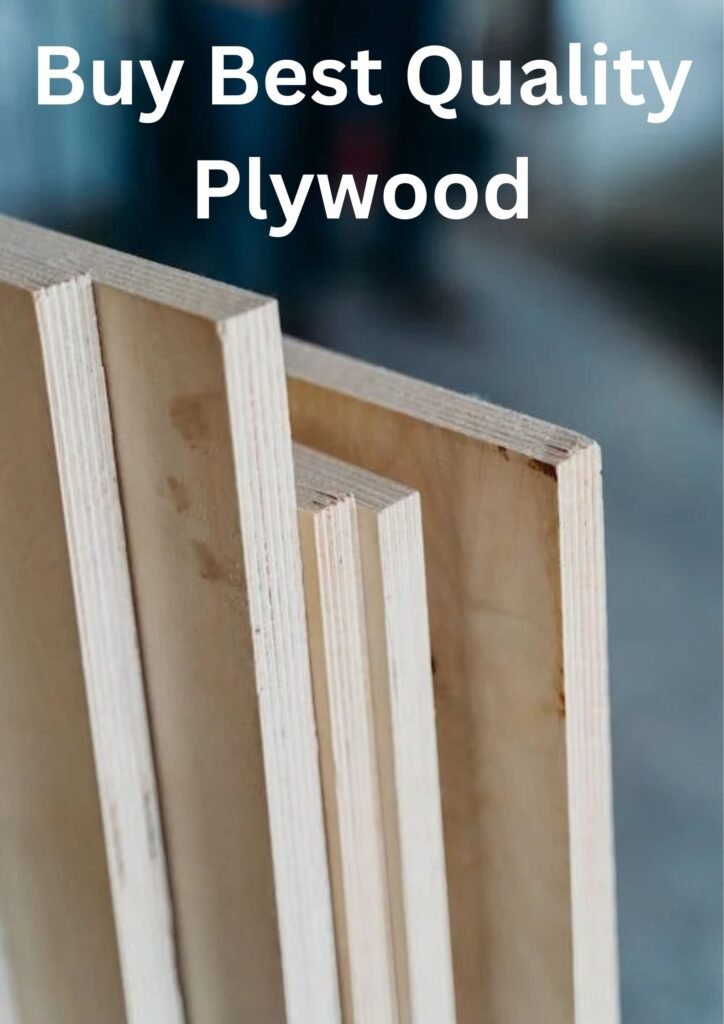

Plywood is an engineered wood panel made by layering thin sheets of wood veneer, called plies, and bonding them together with adhesives under heat and pressure. This manufacturing process results in a sturdy, versatile material with unique properties of plywood that make it suitable for various applications in construction, furniture making, and other industries. However, not all plywood is created equal; it comes in different grades, each with specific characteristics and intended uses. In this article, we’ll explore the four primary grades of plywood, their features, and applications.

Grade A: The Premier Choice for Fine Woodworking

Grade A plywood, also known as cabinet-grade or furniture-grade, represents the highest quality available in the market. This grade is characterized by its exceptional smoothness, absence of defects (such as knots, holes, or patches), and uniform appearance on both faces.

Key Features of Grade A Plywood:

- All plies are made from high-quality veneer, typically from hardwood species like oak, maple, or birch.

- Both faces are sanded to a smooth, flawless finish.

- Edges are solid and clean, with no voids or gaps.

- Ideal for visible applications where aesthetics are crucial.

Applications:

- Cabinetry and furniture making

- Interior woodworking projects

- Decorative paneling

- High-end flooring

- Artistic projects and crafts

Grade B: The Versatile Choice for Interior Applications

Grade B plywood, also known as interior-grade or cabinet-grade on one side, offers a balance between quality and cost. While it may have minor defects, it is still suitable for many interior applications where one side needs to be presentable.

Key Features of Grade B Plywood:

- One face is smooth and free of defects, while the other may have knots, patches, or other imperfections.

- Edges may have some voids or gaps, but they are typically well-filled.

- Made from a combination of hardwood and softwood veneers.

Applications:

- Cabinets (with the smooth side facing out)

- Shelving and built-in furniture

- Wall paneling

- Interior door and window components

- Utility projects (e.g., workbenches, storage units)

Grade C: The Economical Choice for Utility Applications

Grade C plywood, also known as utility-grade or construction-grade, is designed for applications where appearance is not a primary concern. This grade offers a cost-effective solution for projects that prioritize functionality over aesthetics.

Key Features of Grade C Plywood:

- Both faces may have knots, patches, and other defects.

- Edges may have voids or gaps, but they are typically well-filled.

- Made from a combination of hardwood and softwood veneers, often with more softwood plies.

Applications:

- Concrete formwork

- Structural sheathing

- Subflooring and underlayment

- Packaging and crating

- Temporary structures and outdoor projects

Grade D: The Budget-Friendly Choice for Rough Applications

Grade D plywood, also known as mill-grade or economy-grade, is the most affordable and basic option. It is primarily used for applications where strength and durability are more important than appearance.

Key Features of Grade D Plywood:

- Both faces may have numerous knots, patches, and other defects.

- Edges may have significant voids or gaps, with minimal filling.

- Made from a combination of hardwood and softwood veneers, often with more softwood plies.

Applications:

- Temporary construction structures

- Concrete formwork

- Rough framing and bracing

- Outdoor projects (e.g., sheds, fences)

- Packaging and crating

Properties of Plywood: What Makes It Unique?

Regardless of its grade, plywood possesses several unique properties that contribute to its widespread use in various industries. These properties include:

- Strength and Durability: The cross-grain construction of plywood, with alternating grain directions in each ply, provides excellent strength and resistance to splitting, cracking, and delamination.

- Dimensional Stability: Plywood is less prone to warping, shrinking, or swelling compared to solid wood, thanks to its alternating grain pattern and the adhesives used in its construction.

- Versatility: Plywood can be cut, shaped, and finished in various ways, making it suitable for a wide range of applications, from construction to furniture making.

- Cost-Effectiveness: Plywood is generally more affordable than solid wood, especially in larger panel sizes, making it an economical choice for many projects.

- Moisture Resistance: Some plywood types, such as exterior-grade or marine-grade, are designed to withstand moisture and weather conditions, expanding their applications to outdoor environments.

Conclusion

Understanding the four grades of plywood – Grade A, Grade B, Grade C, and Grade D – is crucial for selecting the appropriate material for your specific project. Each grade offers unique features and properties, catering to different applications and budget considerations. By recognizing the strengths and limitations of each grade, you can make an informed decision that balances quality, functionality, and cost-effectiveness.

Remember, the properties of plywood, such as strength, durability, dimensional stability, and versatility, make it a popular choice across various industries. Whether you’re embarking on a fine woodworking project or a construction job, plywood offers a reliable and adaptable solution to meet your needs.

Q1: Can different grades of plywood be used interchangeably for a project?

A1: No, it is generally not recommended to use different grades of plywood interchangeably for the same project. Each grade is designed for specific applications, and using an inappropriate grade may compromise the project’s integrity, appearance, or performance.

Q2: Is it possible to improve the grade of plywood by sanding or finishing it?

A2: No, the grade of plywood is determined by the quality of the veneers and the manufacturing process. Sanding or finishing cannot upgrade the grade, as it does not address the underlying defects or quality of the plies.

Q3: Which grade of plywood is suitable for outdoor use?

A3: For outdoor applications, it is recommended to use exterior-grade or marine-grade plywood, which is designed to withstand moisture and weather conditions. These grades are treated with waterproof adhesives and may include additional protective coatings.

Q4: Can plywood be used for structural applications?

A4: Yes, certain grades of plywood, such as structural-grade or sheathing-grade, are specifically designed for use in structural applications like subflooring, roof and wall sheathing, and concrete formwork. These grades meet specific strength and performance requirements for construction purposes.

Q5: How can I identify the grade of plywood I have?

A5: Most plywood panels are stamped or labeled with their grade on the surface or edges. If the grade is not clearly marked, you can inspect the appearance of the faces and edges, referring to the characteristics described for each grade. Additionally, consulting with the manufacturer or supplier can help determine the grade accurately.

![Detailed Guide to Yamunotri: The First Dham [Complete Travel Guide] 34 Detailed Guide to Yamunotri: The First Dham [Complete Travel Guide]](https://guest-post.org/wp-content/uploads/2024/07/Char-Dham-150x150.png)