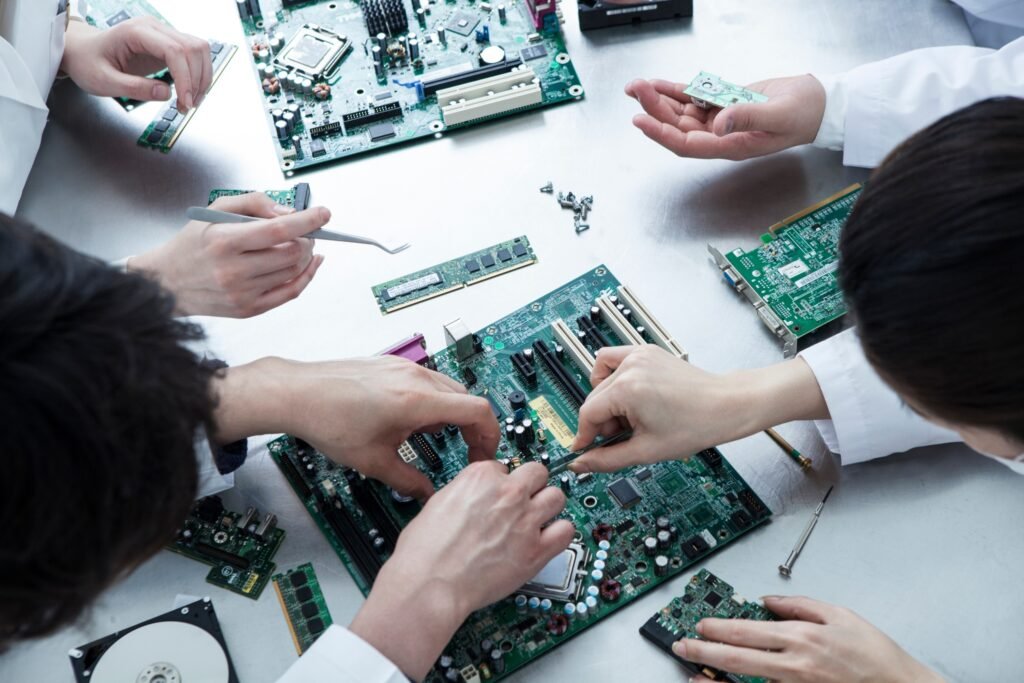

PCB assembly or PCBA is the process of putting together a printed circuit board (PCB). The main goal of PCBA is to have all of the electronic components on the PCB connected in such a way that they function correctly. This requires that all of the parts be soldered to pads on the PCB and that traces be routed between them.

Benefits of PCB assembly

Printed circuit board assembly offers a myriad of benefits and advantages for electronic devices. One key advantage is the enhanced reliability that PCBs provide due to their precise assembly process, reducing the risk of loose connections or short circuits. Additionally, PCBA allows for compact designs with high circuit density, making them ideal for portable devices where space is limited.

Moreover, PCBAs are cost-effective in mass production compared to hand-wired circuits, saving time and resources during manufacturing. The standardized design of PCBs also simplifies troubleshooting and maintenance processes, leading to quicker repairs and reduced downtime for electronic devices.

Furthermore, PCBA enables faster signal transmission speeds and improved electromagnetic interference (EMI) shielding due to the controlled impedance characteristics of printed circuit boards. This results in better overall performance and functionality of electronic products utilizing PCBA technology.

Troubleshooting & maintenance tips for PCBA

When it comes to troubleshooting and maintaining printed circuit board assembly, there are a few key tips to keep in mind. First, always double-check the solder connections for any potential issues like cold joints or shorts. These can often be the cause of malfunctioning PCBs.

Further, regularly inspect the components on the board for signs of damage or wear. Any burnt-out components should be replaced promptly to prevent further damage to the circuit.

It’s also crucial to ensure that all components are correctly aligned and securely fastened on the board. Loose components can lead to connectivity problems and affect the overall functionality of the device.

Regularly cleaning your PCBA using appropriate methods and materials can help prevent dust buildup or corrosion, which can impact performance over time. Staying updated with firmware updates and software patches specific to your PCB can address any compatibility issues that may arise.

By following these maintenance tips, you can prolong the lifespan of your PCBA and ensure optimal performance for your electronic devices.

Future developments in PCBA technology

As technology advances at a rapid pace, the future of PCB assembly looks promising with innovative developments on the horizon. One exciting trend is the move towards smaller and more compact components, allowing for increased functionality in smaller devices.

Also, automation and robotics are playing a significant role in streamlining the assembly process, reducing human error, and increasing efficiency. This shift towards smart manufacturing processes not only speeds up production but also ensures higher quality control standards.

Further, advancements in materials science are leading to new types of substrates that offer improved performance and durability. From flexible PCBs to integrated sensors within the board itself, these innovations are reshaping how electronic devices are designed and manufactured.

With Industry 4.0 technologies such as IoT integration and data analytics becoming more prevalent, we can expect to see even greater connectivity and intelligence embedded within PCB assemblies. These developments will undoubtedly revolutionize various industries reliant on electronics for their operations.

Conclusion: The importance of high-quality PCBA for electronic devices

In today’s rapidly advancing technological landscape, the role of printed circuit board assembly is more crucial than ever. As electronic devices become increasingly complex and compact, the need for high-quality PCBA services becomes paramount.

By ensuring that your electronic devices are equipped with a reliable and well-assembled PCB, you can enhance their performance, longevity, and overall functionality. High-quality PCBA not only improves the efficiency of your device but also reduces the risk of malfunctions or failures.

Investing in top-notch PCBA services can ultimately save you time and money by minimizing the need for repairs or replacements down the line. Whether you are a manufacturer looking to produce cutting-edge electronics or an end-user seeking optimal performance from your devices, prioritizing high-quality PCBA is key.

Remember, when it comes to electronics, the quality of the PCB assembly plays a significant role in determining the success and reliability of the final product. So next time you’re considering electronic device development or repair, make sure to prioritize high-quality printed circuit board assembly for superior results.

![Detailed Guide to Yamunotri: The First Dham [Complete Travel Guide] 34 Detailed Guide to Yamunotri: The First Dham [Complete Travel Guide]](https://guest-post.org/wp-content/uploads/2024/07/Char-Dham-150x150.png)