India’s construction industry is evolving rapidly, with sustainability taking center stage. One major shift is the increasing use of fly ash bricks, an eco-friendly alternative to traditional clay bricks. With growing environmental concerns and government policies favoring sustainable materials, the market for fly ash bricks in India is set to boom in 2025. But what makes fly ash bricks the future of construction? Let’s explore!

Understanding Fly Ash Bricks

Fly ash bricks are made from fly ash (a byproduct of coal combustion), cement, sand, and lime. Unlike traditional clay bricks, they don’t require high-temperature kilns, making them more environmentally friendly.

Key Properties of Fly Ash Bricks:

✅ High Strength: More durable than red bricks.

✅ Lightweight: Easier to transport and work with.

✅ Thermal Insulation: Keeps homes cooler in summers.

✅ Water Resistant: Absorbs less moisture, reducing wall dampness.

Market Growth and Demand for Fly Ash Bricks in India (2025)

The demand for fly ash bricks in India is growing due to:

- Rising urbanization: India’s urban population is expected to hit 600 million by 2031, increasing the need for sustainable housing.

- Government policies: Mandates promoting the use of fly ash bricks in construction.

- Smart Cities Mission: Increased adoption in infrastructure projects.

- Thermal power plant byproducts: India generates 180 million tones of fly ash annually, ensuring a steady supply.

Expected Market Growth:

📈 CAGR of 6-8% between 2023-2028.

🏗 Estimated market size to reach ₹50,000 crores by 2025.

Benefits of Fly Ash Bricks Over Conventional Bricks

1. Environmental Benefits

✅ Reduces Carbon Footprint: Fly ash bricks emit 90% less CO₂ compared to clay bricks.

✅ Prevents Soil Degradation: No need for topsoil excavation.

✅ Utilizes Industrial Waste: Effectively recycles over 100 million tonnes of fly ash annually.

2. Economic Benefits

✅ Lower Cost of Construction: Requires less mortar and plaster.

✅ Energy Efficient: Reduces air conditioning costs by 10-15% due to better insulation.

✅ Government Subsidies: Many states offer tax benefits and subsidies for using fly ash bricks.

3. Structural and Performance Benefits

✅ High Compressive Strength: 7-10 MPa, compared to 3-5 MPa in clay bricks.

✅ Earthquake Resistant: Better shock absorption in seismic-prone areas.

✅ Uniform Size & Shape: Ensures faster construction with minimal material wastage.

Market Trends and Forecast for 2025

1. Adoption in Urban & Rural Infrastructure

🏢 Commercial and residential buildings are shifting towards fly ash bricks for sustainable construction.

🏡 Rural housing schemes like PMAY (Pradhan Mantri A was Yojana) are boosting demand.

🚧 Government road and bridge projects increasingly use fly ash bricks.

2. Technological Advancements

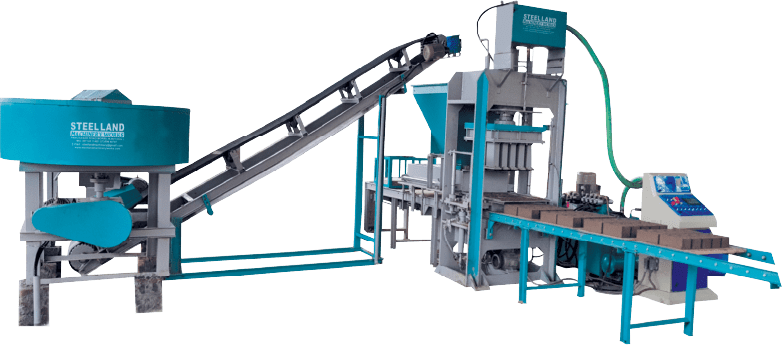

🔹 Automated block-making machines are improving production efficiency.

🔹 AI-driven quality checks ensure consistent strength and durability.

🔹 Prefabricated fly ash blocks are gaining traction in modular construction.

3. Leading Regions in India Using Fly Ash Bricks

📍 Maharashtra, Gujarat, Tamil Nadu, Karnataka, Delhi, and Uttar Pradesh are major markets.

📍 Eastern India (West Bengal, Odisha, Bihar) is witnessing increased adoption due to power plant proximity.

Government Policies & Regulations Driving Growth

📜 Bureau of Indian Standards (BIS): Mandates fly ash usage in bricks under IS 12894.

📜 National Green Tribunal (NGT): Imposes restrictions on traditional brick kilns.

📜 MoEF&CC Guidelines: Recommends mandatory 20% fly ash usage in all construction projects near thermal plants.

📜 Smart Cities & AMRUT Mission: Promotes sustainable building materials in urban projects.

Challenges in the Fly Ash Brick Industry

Despite the benefits, there are a few hurdles:

❌ Limited Awareness: Many builders still prefer traditional bricks.

❌ Supply Chain Issues: Transportation costs increase in regions far from thermal power plants.

❌ Standardization Challenges: Need for better quality control across suppliers.

However, increasing government support and technological advancements are helping overcome these barriers.

How to Choose the Best Fly Ash Bricks for Your Project

Factors to Consider:

- ✅ Strength & Durability – Ensure a compressive strength of 7-10 MPa.

- ✅ Certification & Standards – Look for BIS & ISO certifications.

- ✅ Moisture Absorption Rate – Should be below 12%.

- ✅ Reliable Suppliers – Work with trusted block-making machine manufacturers in India.

The Future of Fly Ash Bricks in India

1. AI & Automation in Brick Manufacturing

🤖 Automated fly ash brick machines are reducing labor dependency.

🔬 AI-based quality control ensures uniformity and strength.

2. Mass Adoption in Affordable Housing

🏡 India needs 25 million+ affordable homes by 2030 – fly ash bricks will play a key role.

🏗 Builders prefer sustainable options to meet green building certifications.

3. Export Opportunities for Indian Fly Ash Bricks

🌍 Countries like UAE, Bangladesh, and Nepal are importing fly ash bricks from India.

🚢 Indian manufacturers expanding to global markets due to cost-effectiveness.

Conclusion

Fly ash bricks are revolutionizing India’s construction industry. With rising demand, government support, and eco-friendly benefits, they are set to replace traditional bricks in the coming years. If you’re in the construction business, now is the time to shift to fly ash bricks. Work with reputed block-making machine suppliers and ensure sustainable, cost-effective, and high-quality construction for the future!