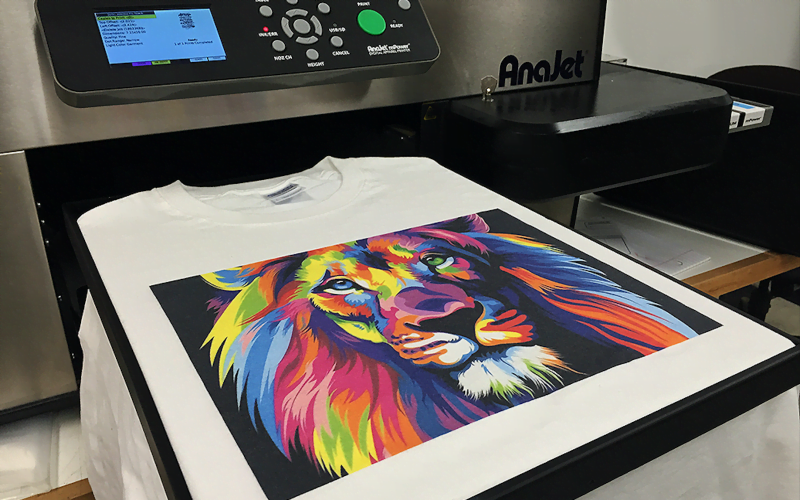

Direct-to-Garment (DTG) printing has revolutionized the world of custom apparel by offering a convenient and versatile method for printing high-quality designs directly onto fabric. From intricate artwork to vibrant photographs, DTG printing allows for detailed and colorful designs to be reproduced with precision. In this comprehensive guide, we’ll delve into the intricate process of custom DTG printing on shirts, covering each step from design preparation to the final printed product, while exploring equipment, materials, and best practices for achieving professional results.

Understanding DTG Printing:

- DTG printing is a digital printing method that involves applying water-based ink directly onto the fabric of a garment using a specialized inkjet printer. Unlike traditional screen printing, which requires separate screens for each color, DTG printing allows for full-color designs to be printed in a single pass. This makes it ideal for printing complex designs, photographs, and intricate artwork with fine detail.

Design Preparation:

- The DTG printing process begins with the preparation of the design to be printed. Designs can be created digitally using graphic design software or provided by the customer. It’s essential to ensure that the design is high-resolution and properly formatted for printing. This may involve adjusting colors, resizing, and optimizing the design for the specific garment size.

Pre-Treatment:

- Before printing, the garment needs to be pre-treated with a special solution to ensure proper ink adhesion and vibrant colors. The pre-treatment solution helps the ink to bond with the fabric and prevents bleeding or fading during the printing process. The garment is typically placed on a heat press, and the pre-treatment solution is applied evenly to the printing area.

Printing Process:

- Once the pre-treatment is applied and dried, the garment is ready for printing. The design file is loaded into the DTG printer, and the garment is placed onto the printing platen. The printer applies the ink directly onto the fabric, layer by layer, using precise droplets of ink to reproduce the design with exceptional detail and color accuracy.

Curing:

- After printing, the garment undergoes a curing process to set the ink and ensure durability. This typically involves heat pressing the printed area at a specific temperature and pressure for a predetermined amount of time. Curing the ink helps to bond it to the fabric fibers, resulting in vibrant and long-lasting prints.

Quality Control:

- Throughout the printing process, operators monitor the print quality and make adjustments as needed to ensure consistent results. After printing and curing, each garment undergoes thorough inspection to check for any defects, misprints, or inconsistencies. Quality control measures help to ensure that the final product meets the desired standards of clarity and durability.

Post-Processing:

- Once the printing and curing are complete, any excess pre-treatment solution or ink residue is removed from the garment. The garment may undergo post-processing steps such as steaming or pressing to further enhance the appearance and feel of the print. Finally, the garment is folded, labeled, and packaged for distribution or retail sale.

Conclusion:

Custom DTG printing offers a convenient and efficient method for creating high-quality, full-color designs on shirts and other garments. By following the steps outlined in this guide and adhering to best practices, printers can achieve professional results that meet the unique needs and preferences of their customers. Whether it’s for personal use, promotional merchandise, or retail apparel, DTG printing provides endless possibilities for creativity and customization in the world of custom apparel decoration.

![Detailed Guide to Yamunotri: The First Dham [Complete Travel Guide] 34 Detailed Guide to Yamunotri: The First Dham [Complete Travel Guide]](https://guest-post.org/wp-content/uploads/2024/07/Char-Dham-150x150.png)