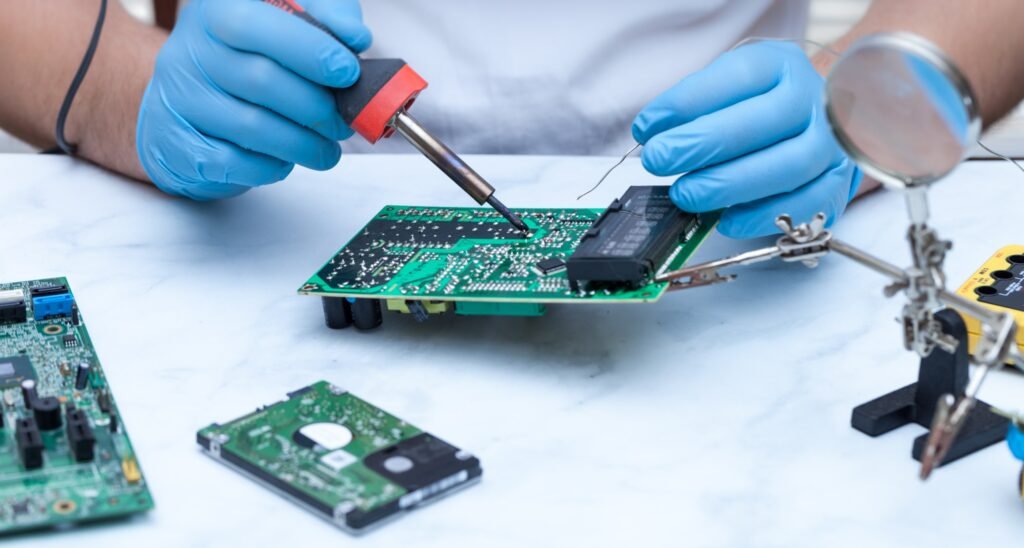

Electronic manufacturing services or EMS provide businesses with access to the required resources at a lower cost than if they had them internally. For example, an electronics manufacturer could outsource the production of circuit boards to an EMS provider instead of spending money on hiring skilled engineers and buying expensive machinery.

EMS is the process of designing, assembling and packaging electronic components into products. EMS is a global industry that can provide companies with a wide range of solutions from design to final assembly.

The benefits of using an EMS are:

– Cost savings: Using EMS can reduce costs by 30% to 90%, depending on the country where it is based.

– Speed to market: The time between designing and actually producing a product can be reduced significantly by outsourcing production to an EMS provider.

– Quality control and testing: Companies will have more control over quality assurance if they work directly with an EMS provider who has experience handling similar types of products before.

Choosing an Electronic Manufacturing Services or EMS Partner

When evaluating potential electronic manufacturing services (EMS) providers, original equipment manufacturers (OEMs) should consider several key factors to ensure a successful partnership. Choosing the right EMS partner is crucial for meeting production goals, quality standards, and time-to-market objectives.

Technology Expertise

A top priority is assessing the EMS provider’s technology expertise and capabilities. OEMs should evaluate the provider’s experience with the required manufacturing processes, such as SMT, thru-hole, box build, testing, etc. Understanding the provider’s capabilities with emerging and legacy technologies is also important.

Quality Systems

The EMS company should have robust quality systems and controls in place, such as ISO 9001 or AS9100 certification. They should be able to provide evidence of their quality performance through metrics like defect rates, yields, and customer scorecards. Site audits can validate capabilities.

Global Footprint

Selecting an EMS company with production facilities near target markets can help shorten supply chains and enable flexibility. OEMs should consider the provider’s global footprint and evaluate needs for regional vs. low-cost manufacturing.

Financial Stability

Since the EMS provider essentially becomes an extension of the OEM’s operations, their financial health is critical. OEMs should assess the company’s financial statements to ensure stability and minimize supply disruption risks. Longstanding EMS providers with proven financial track records can provide the greatest assurance.

The ideal EMS partner will offer expertise across these areas to deliver exceptional manufacturing support and value. Carefully qualifying potential providers on key criteria ensures an optimal match for the OEM’s specific needs and goals.

The EMS Development Process

EMS providers are involved in all stages of the product development process, from design to volume production. A key benefit of partnering with an EMS is leveraging their expertise during product development to optimize manufacturing and avoid issues later on.

Design for Manufacturing

Design for manufacturing (DFM) refers to designing products in a way that optimizes them for manufacturing efficiency and quality. EMS providers offer DFM analysis and recommendations early in the design process. This allows potential manufacturability issues to be identified and addressed while changes are still relatively easy to make.

DFM guidelines provided by an EMS may relate to things like:

– Component selection – Recommending easily sourced and reliable components

– Design tolerances – Ensuring tolerances align with manufacturing capabilities

– Ease of assembly – Designing products that are straightforward to assemble

– Testability – Incorporating test points and other design aspects to support testing

Following DFM guidelines prevents redesigns late in the development process and results in a product optimized for manufacturability.

Prototyping

Prototyping involves building early iterations of a product for concept validation, testing, and refinement. EMS providers have fast-turn prototype capabilities spanning from simple circuit boards to complete, fully-functional products.

Leveraging an EMS for prototyping provides several benefits:

– Faster time-to-market by outsourcing prototyping

– Utilizing the same manufacturer as production minimizes variability

– EMS engineering support for refining and optimizing the design

– Flexible low-to-mid volume production for field testing and trials

Multiple iterations of prototypes can be developed in parallel with engineering refinement to accelerate product development.

Ramping to Volume

Once the product design is finalized, the EMS partner can rapidly ramp up production volumes. They are experts in scaling production in a managed, optimized way.

Key aspects of ramping up volume include:

– Putting long-lead components and materials on order

– Expanding manufacturing space, equipment, and staff as needed

– Refining processes to meet higher output levels

– Implementing robust quality systems for consistent execution

– Managing supply chain logistics for increased material flows

A strategic EMS partner will help scale efficiently to meet time-to-market and cost targets. Their volume flexibility allows starting low rate initial production and rapidly scaling to mass production.

Managing the EMS Relationship

Successful partnerships between OEMs and EMS providers rely on consistent, open communication and alignment. Here are some best practices for managing the relationship:

Communication

– Have regularly scheduled meetings or calls to discuss the status of projects, potential issues, and upcoming needs. Daily or weekly touchpoints are ideal.

– Document agreements, timelines, specifications, and other details so both parties share expectations.

– Address problems early and escalate concerns before they become major conflicts. Be transparent about challenges.

– Share feedback, both positive and constructive, so the EMS provider can continuously improve.

Forecasting

– Provide the EMS with forecasts of production needs and order volumes. The more accurate and far in advance, the better they can prepare.

– Factor in seasonality, promotions, product life cycles, and other dynamics that may impact orders. Avoid drastic fluctuations.

– Revise forecasts frequently as market conditions change. Collaborate on adjusting capacity as needed.

Change Management

– Have a structured process for proposing, reviewing, approving, and implementing engineering changes and design modifications.

– Minimize changes once production begins. Follow change order procedures.

– For major changes, give sufficient lead time and assess impact on the supply chain.

– Carefully test changes to ensure no unintended side effects.

– Align on configuration management to track versions and changes.

With robust coordination, communication, and planning, OEMs and EMS providers can optimize efficiency, quality, and responsiveness. Fostering collaboration enables each partner to focus on their core strengths.

Quality Considerations with EMS

Quality is a critical consideration when working with an EMS provider. Selecting an EMS partner with robust quality systems and controls in place helps ensure the final product meets specifications and customer expectations.

Quality Management System

A comprehensive quality management system (QMS) is essential for any EMS provider. This includes documented procedures for quality control activities across all areas of manufacturing, from procurement through production and final delivery. Leading EMS companies will have QMS certification such as ISO 9001 or similar to demonstrate compliance with quality standards.

Process Controls

EMS providers should have strict process controls and testing at every stage of production. This includes inspection of incoming components, in-process inspection during assembly, and final testing of completed boards or systems. Automated optical inspection (AOI) and automated x-ray inspection (AXI) enable detection of defects and process issues. Regular process audits help ensure consistent quality output.

Corrective Action

When quality issues arise, robust corrective action procedures are critical. EMS providers must be able to quickly identify root causes of problems, implement solutions to prevent recurrence, and take action regarding impacted materials or products. Continuous improvement processes allow EMS companies to constantly refine procedures to enhance quality over time. Close collaboration and transparency with the customer is key during any quality issue resolution.

Selecting an electronic manufacturing services or EMS partner that emphasizes quality at all levels results in a more efficient development process and higher reliability in the final product. Ongoing communication and active quality management alignment between customer and EMS provider ensures quality objectives are met.