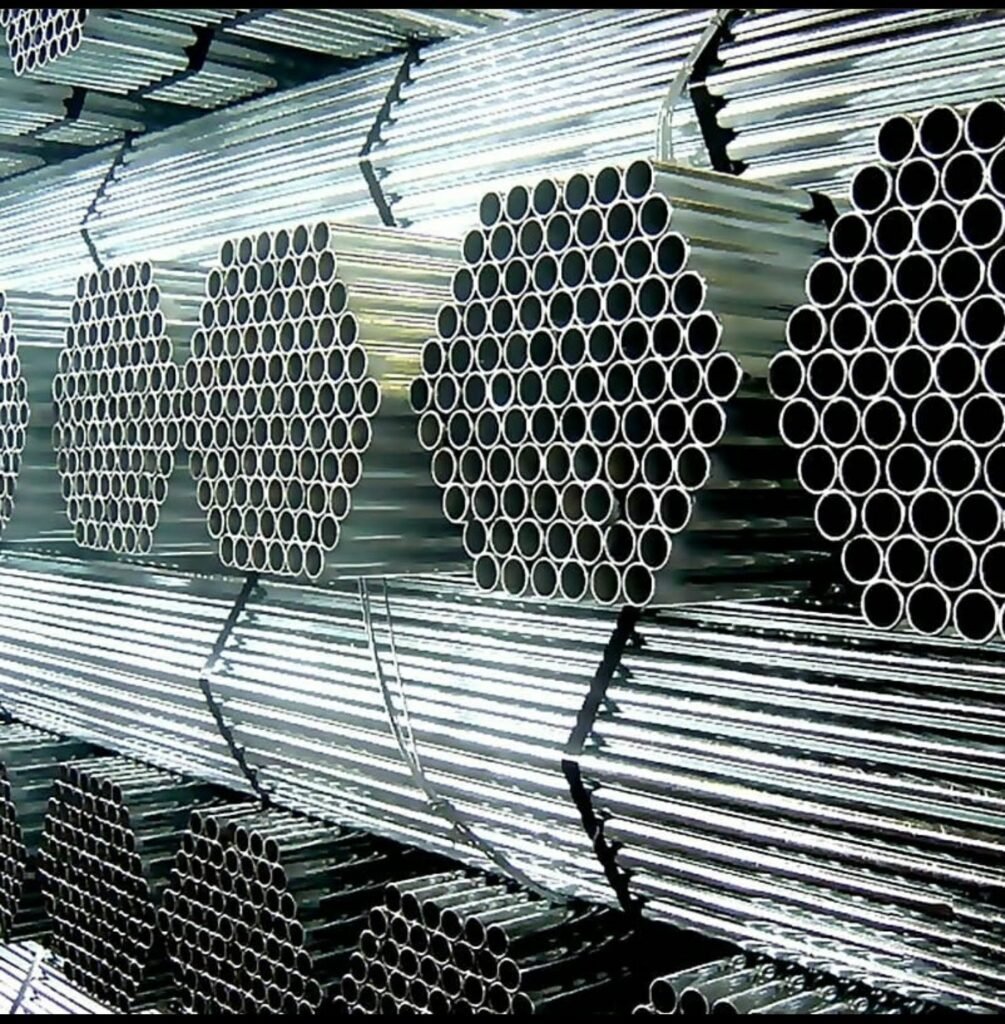

Stainless Steel 316Ti Welded Pipes are widely used in industries that demand excellent heat resistance and corrosion protection. Their superior mechanical properties and high-temperature durability make them a preferred choice in many critical applications. This blog explores why Stainless Steel 316Ti Welded Pipes are ideal for high-temperature environments and how they outperform other materials in such conditions.

Understanding Stainless Steel 316Ti Welded Pipes

Stainless Steel 316Ti Welded Pipes are made from an advanced variation of the standard 316 stainless steel, with the addition of titanium. This alloy enhances the material’s strength and resistance to high temperatures, making it highly effective in demanding applications. These pipes are known for their superior weldability, ensuring strong and durable joints that can withstand thermal expansion and stress.

Key Properties for High-Temperature Applications

- Enhanced Heat Resistance

The presence of titanium in Stainless Steel 316Ti Welded Pipes prevents carbide precipitation at high temperatures, ensuring long-term stability. This property makes these pipes highly effective in applications exposed to prolonged heat, such as heat exchangers, boiler systems, and furnace components. - Superior Corrosion Resistance

One of the main advantages of Stainless Steel 316Ti Welded Pipes is their excellent resistance to oxidation and corrosion. These pipes perform well in environments with high humidity, aggressive chemicals, and fluctuating temperatures, making them suitable for industries like petrochemicals, power generation, and chemical processing. - Excellent Mechanical Strength

High-temperature applications demand materials that maintain their strength and structural integrity under extreme conditions. Stainless Steel 316Ti Welded Pipes offer high tensile strength and durability, preventing deformations and failures in industrial setups. - Extended Service Life

The superior composition of Stainless Steel 316Ti Welded Pipes ensures long-term performance, reducing maintenance costs and frequent replacements. Their durability in extreme heat and pressure conditions extends the overall lifespan of industrial systems.

Applications of Stainless Steel 316Ti Welded Pipes in High-Temperature Environments

- Power Plants: Used in steam piping, heat exchangers, and boiler tubes to handle high temperatures and pressures efficiently.

- Chemical and Petrochemical Industry: Ideal for processing corrosive chemicals at elevated temperatures without degradation.

- Aerospace and Automotive Industry: Used in exhaust systems and other components where heat resistance is crucial.

- Food Processing Equipment: Ensures hygiene and durability in high-temperature sterilization processes.

- Oil and Gas Sector: Used in refineries, offshore platforms, and high-temperature pipelines for safe and efficient fluid transportation.

Why Choose Stainless Steel 316Ti Welded Pipes Over Other Materials?

- Better Than Standard 316 Stainless Steel

While standard 316 stainless steel offers good corrosion resistance, it is prone to carbide precipitation at high temperatures, leading to intergranular corrosion. The addition of titanium in Stainless Steel 316Ti Welded Pipes prevents this issue, ensuring stability and performance at elevated temperatures. - More Durable Than 304 Stainless Steel

Stainless Steel 304 is a common choice for general applications, but it lacks the high-temperature strength of Stainless Steel 316Ti Welded Pipes. The enhanced mechanical properties of 316Ti make it the better option for heat-intensive environments. - Weldability and Fabrication Advantages

Stainless Steel 316Ti Welded Pipes offer excellent weldability without requiring post-weld heat treatment. This makes them easy to fabricate and integrate into complex industrial systems, reducing downtime and installation costs. - High Resistance to Thermal Fatigue

These pipes maintain their structural integrity even under repeated heating and cooling cycles, reducing the risk of cracking or failure in high-temperature operations. - Improved Creep Strength

The titanium addition enhances the material’s resistance to deformation under prolonged stress and heat, making it suitable for critical high-temperature applications. - Minimal Maintenance Requirements

Due to their excellent corrosion and oxidation resistance, Stainless Steel 316Ti Welded Pipes require less frequent maintenance, reducing operational costs. - Environmentally Friendly and Recyclable

Stainless steel is 100% recyclable, making these pipes a sustainable choice for industries looking to minimize their environmental impact.

Conclusion

Stainless Steel 316Ti Welded Pipes are the ideal choice for high-temperature applications due to their outstanding heat resistance, corrosion protection, and mechanical strength. Their durability and long service life make them a cost-effective solution for industries operating under extreme conditions. Whether used in power plants, chemical processing, or oil and gas sectors, these pipes offer unmatched performance and reliability. Investing in Stainless Steel 316Ti Welded Pipes ensures long-term efficiency and safety in demanding industrial environments.