In the rapidly evolving world of manufacturing, 5 axis CNC machining Services are transforming how industries approach precision, complexity, and customization. As industries shift toward tighter tolerances, faster production cycles, and intricate geometries, multi-axis CNC machining services have become indispensable. These advanced solutions are empowering aerospace, medical, defense, and automotive sectors to meet demanding specifications with ease and consistency.

What Sets 5 Axis CNC Machining Services Apart?

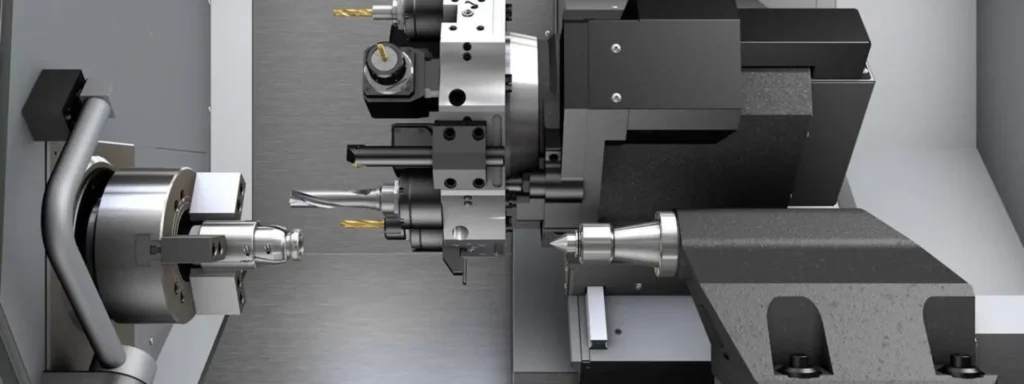

Unlike traditional 3-axis machines, 5 axis CNC machining Services operate along five different axes simultaneously—X, Y, Z, and two rotational axes (A and B). This allows for exceptional flexibility, enabling intricate components to be crafted in a single setup. The result is reduced lead times, fewer errors, and superior surface finishes.

Using precision 5 axis CNC machining, manufacturers can achieve tighter tolerances on parts with complex contours, undercuts, or deep cavities. The high-speed spindles and intelligent software used in custom 5 axis machining services further enhance accuracy, while also minimizing material waste and manual rework.

Applications Across Industries

Aerospace and Defense

The aerospace industry demands top-tier performance and flawless execution. 5 axis CNC machining Services are ideal for producing turbine blades, engine mounts, and aerospace brackets where complex geometries and material strength are non-negotiable. With multi-axis CNC machining services, these parts can be produced faster and with unparalleled consistency.

Medical and Surgical Equipment

Medical device manufacturers rely heavily on precision 5 axis CNC machining for crafting tools, implants, and orthopedic components. The ability to machine biocompatible materials like titanium and surgical-grade stainless steel makes custom 5 axis machining services an essential part of medical innovation.

Automotive and Motorsport

From high-performance engine components to intricate suspension parts, 5 axis CNC machining Services help automotive engineers achieve higher reliability and performance. Whether it’s a prototype or a full production run, this technology supports lightweighting and optimal strength-to-weight ratios.

Advantages of Multi-Axis CNC Machining Services

Choosing multi-axis CNC machining services brings numerous benefits to manufacturing workflows:

-

Reduced setups: Complex parts are machined in one go, eliminating multiple repositionings.

-

Enhanced accuracy: The fewer the setups, the fewer the opportunities for human error.

-

Shorter cycle times: Faster production means quicker delivery to market.

-

Versatility: Whether it’s aluminum, titanium, stainless steel, or plastics—multi-axis machines handle it all.

With 5 axis CNC machining Services, parts that once required manual intervention or multiple operations can now be completed efficiently and to exact specifications.

Custom 5 Axis Machining Services for Complex Projects

Every project comes with unique challenges. That’s where custom 5 axis machining services come into play. Whether you’re prototyping a new design or scaling up for production, custom machining allows tailored solutions to meet your specifications—down to the micron level.

A trusted 5 axis CNC machining company will offer solutions designed around your product, not the limitations of their equipment. This means faster turnaround times, fewer revisions, and ultimately, a more competitive product.

Choosing the Right 5 Axis CNC Machining Company

When seeking a reliable 5 axis CNC machining company, it’s important to look beyond capabilities. Here’s what separates leading providers from the rest:

-

Experience: Years of experience often translate to process knowledge and problem-solving agility.

-

Technology investment: Top-tier machinery and CAM software make a significant difference.

-

Quality control: ISO-certified processes and in-process inspection ensure part integrity.

-

Engineering support: A skilled team can help optimize designs for manufacturability.

These attributes ensure that your investment in 5 axis CNC machining Services delivers long-term value.

How Precision 5 Axis CNC Machining Drives Quality

In today’s precision-driven markets, even the smallest deviation can lead to product failure or customer dissatisfaction. That’s why precision 5 axis CNC machining is critical. These machines achieve incredibly tight tolerances and surface finishes that meet the highest standards.

Whether it’s matching GD&T specs or ensuring consistent part geometry across a batch, 5 axis CNC machining Services provide unmatched repeatability and finish quality. In industries where safety and performance are critical, this level of precision isn’t optional—it’s essential.

Innovation Through Automation

Modern 5 axis CNC machining Services are integrated with intelligent software and automation technologies. From toolpath optimization to real-time monitoring, automation minimizes downtime, reduces scrap rates, and enhances productivity.

With the rise of Industry 4.0, 5 axis CNC machining companies are now integrating IoT and AI for predictive maintenance, adaptive machining, and automated quality checks. This forward-thinking approach ensures scalable and sustainable production without compromising quality.

Sustainability and Material Efficiency

Sustainability is no longer a luxury—it’s a requirement. Custom 5 axis machining services optimize material usage, reducing waste and energy consumption. By eliminating unnecessary setups and tool changes, machines consume fewer resources and operate more efficiently.

Advanced toolpath strategies also contribute to this by reducing cycle times and extending tool life, aligning with broader green manufacturing initiatives. Choosing 5 axis CNC machining Services isn’t just good for business—it’s a responsible environmental choice.

Future Trends in Multi-Axis CNC Machining Services

As technology continues to evolve, multi-axis CNC machining services are expected to become even more powerful. Developments in additive-subtractive hybrid machines, AI-driven toolpaths, and material sciences are pushing the boundaries of what’s possible.

In the near future, expect to see custom 5 axis machining services play a greater role in sectors like renewable energy, electronics, and consumer product design. Faster machines, smarter software, and greener processes will define the next era of manufacturing innovation.

Conclusion: Why Invest in 5 Axis CNC Machining Services

Whether you’re looking to accelerate product development, enhance part quality, or reduce manufacturing costs, 5 axis CNC machining Services offer a strategic advantage. With the ability to handle complex parts with speed and accuracy, it’s clear why these services are becoming the gold standard in precision manufacturing.

From concept to completion, manufacturers who leverage multi-axis CNC machining services gain a competitive edge in quality, efficiency, and innovation. For projects that demand nothing less than excellence, precision 5 axis CNC machining is the smart investment.