Introduction to Metal Machining

In the modern manufacturing industry, precision and reliability are paramount. Choosing the right metal machining parts manufacturer can make a significant difference in your business operations. Whether you need custom metal parts or mass production components, a trusted manufacturer can provide the expertise and resources to meet your specific needs. This article explores why it’s essential to partner with a reliable metal machining parts manufacturer and what you should look for when selecting one.

What is Metal Machining?

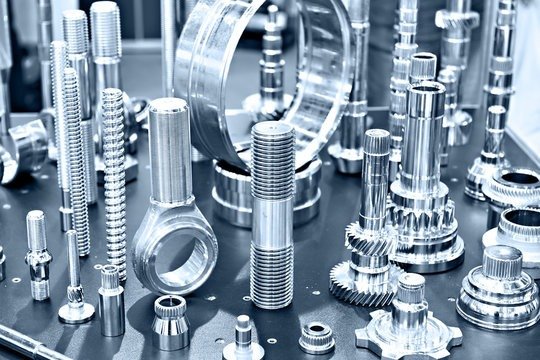

Metal machining is the process of shaping and cutting metal to create components used in various industries such as automotive, aerospace, electronics, and more. The process involves removing material from a workpiece through different methods like milling, turning, drilling, and grinding. The aim is to achieve precise dimensions and surfaces that meet the required specifications. The quality of the machining process significantly impacts the overall performance and durability of the final product.

Why Precision Matters in Metal Machining

Precision is a critical factor when it comes to metal machining. Components often need to fit together with extreme accuracy to ensure they function properly. For example, in the automotive industry, even small deviations can lead to malfunctioning parts or safety issues. A top metal machining parts manufacturer uses state-of-the-art technology such as CNC (Computer Numerical Control) machines to guarantee precision in every part produced. The manufacturer’s commitment to quality ensures that all parts meet strict tolerances and specifications.

Key Features of a Trusted Metal Machining Parts Manufacturer

When selecting a metal machining parts manufacturer, you need to consider several factors to ensure they are trustworthy and capable of delivering high-quality products.

- Expertise and Experience: A well-established manufacturer with years of experience in metal machining will have a deep understanding of the various techniques and materials used. They will also be able to handle a wide range of projects, from small custom parts to large-scale production runs.

- Advanced Technology: The best manufacturers invest in the latest technology to produce parts with high precision and efficiency. CNC machining, laser cutting, and 3D printing are just a few examples of technologies that can improve the quality and speed of production.

- Customization Options: A trusted manufacturer should be able to provide customized solutions that fit your specific needs. Whether you require a unique part or a modification to an existing design, they should offer flexibility in terms of design and production.

- Quality Control: Look for manufacturers who prioritize quality control throughout the entire production process. This includes rigorous testing, inspection, and adherence to industry standards. A reliable manufacturer will have certifications such as ISO 9001 to ensure their processes meet global quality standards.

- Timely Delivery: In today’s fast-paced world, timely delivery is crucial. The best manufacturers have systems in place to ensure that production schedules are met and that customers receive their parts on time. This is especially important for industries where delays can result in costly setbacks.

The Benefits of Partnering with a Trusted Metal Machining Parts Manufacturer

Partnering with a reliable metal machining parts manufacturer can bring numerous advantages to your business:

- Cost Efficiency: Although high-quality machining parts might initially seem more expensive, partnering with a skilled manufacturer can reduce long-term costs. High-precision parts reduce the likelihood of failures, reworks, and warranty claims, leading to cost savings over time.

- Improved Product Quality: A trusted manufacturer will ensure that the machining process meets the highest quality standards. This results in durable, reliable parts that perform well and have a longer lifespan.

- Enhanced Customer Satisfaction: By choosing a reputable manufacturer, you can ensure that the parts you provide to your customers are of the highest quality. This leads to increased customer satisfaction, repeat business, and a strong reputation in the market.

- Faster Time to Market: A dependable manufacturer can speed up the production process, allowing you to bring your products to market faster. With access to the latest technology and a streamlined workflow, they can quickly meet tight deadlines without compromising quality.

Factors to Consider When Choosing a Metal Machining Parts Manufacturer

When choosing a metal machining parts manufacturer, several factors should be taken into account:

- Location: Choosing a local manufacturer can reduce shipping costs and lead times. However, many manufacturers offer global shipping, so location may not always be a limiting factor.

- Reputation: A manufacturer’s reputation in the industry is a good indicator of their reliability and ability to deliver quality products. Look for reviews, testimonials, and case studies to assess their track record.

- Range of Services: The best manufacturers offer a wide range of services, including design assistance, prototyping, and post-production support. They should be able to handle every stage of production, from concept to final product.

- Pricing Structure: While price is always a consideration, it should not be the only deciding factor. Make sure to evaluate the overall value offered by the manufacturer, including their commitment to quality, reliability, and customer service.

- Customer Support: A good metal machining parts manufacturer will provide excellent customer support, answering questions and resolving issues promptly. Clear communication is key to a successful partnership.

Applications of Metal Machining Parts

Metal machining parts are used in a wide variety of industries. Some of the most common applications include:

- Automotive Industry: Precision parts like engine components, chassis, and transmissions are critical to the functioning of vehicles.

- Aerospace: Aerospace components must meet extremely strict standards for safety and performance. Machined metal parts are essential in the production of aircraft engines, landing gear, and structural components.

- Electronics: Metal machined parts are used in electronics for enclosures, connectors, and other critical components that require durability and precision.

- Medical Devices: Many medical devices rely on precise metal parts, including surgical instruments, implants, and diagnostic equipment.

- Energy: Machined metal parts are used in power generation, oil and gas exploration, and renewable energy sectors for turbines, pipes, and fittings.

Conclusion: Finding the Right Metal Machining Parts Manufacturer

Selecting the right metal machining parts manufacturer is crucial for the success of your business. By considering factors such as expertise, technology, quality control, and customer service, you can ensure that you partner with a manufacturer who will meet your needs and exceed your expectations. With the right partner, you can achieve precision, reliability, and cost savings in your production process, helping your business thrive in a competitive market.

Remember, the key to success lies in choosing a manufacturer who not only delivers high-quality products but also understands the unique requirements of your industry. Whether you’re producing custom parts or mass-produced components, a trusted aerospace fasteners manufacturer can help you achieve your goals.