Milk is a part of daily life in India, whether in a cup of chai, a glass of lassi, or a bowl of curd. With India being the largest producer of milk globally, contributing over 23% to world production, maintaining milk quality is crucial. But how do dairy plants and farmers ensure that the milk is pure, free from adulteration, and meets regulatory standards?

The answer lies in milk analyzers – smart devices that test milk quality in real-time. Let’s dive into why milk analyzers are essential for dairy product quality control in India.

Importance of Quality Control in the Dairy Industry

Ensuring milk quality is not just about taste – it’s about safety, nutrition, and fair pricing. According to FSSAI (Food Safety and Standards Authority of India), over 60% of milk samples in India fail to meet quality standards due to adulteration, low fat content, or contamination. This is why technology-driven quality control is becoming a necessity.

What is a Milk Analyzer?

A milk analyzer is an electronic device that quickly measures different milk parameters like fat percentage, SNF (Solids-Not-Fat), water content, protein levels, and density. This helps in determining whether the milk meets quality standards or has been tampered with.

How Do Milk Analyzers Work?

- The milk sample is inserted into the analyzer.

- The device uses ultrasonic or infrared technology to evaluate milk properties.

- Results are displayed instantly, ensuring quick decision-making.

Types of Milk Analyzers Used in India

- Portable Milk Analyzers – Small, easy to carry, and best for dairy farmers.

- Ultrasonic Milk Analyzers – More accurate and widely used in milk collection centers.

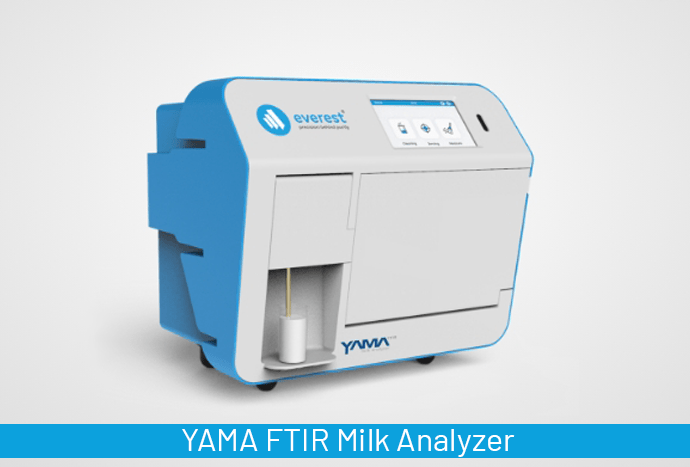

- Infrared Milk Analyzers – Used in dairy plants for precise testing.

- Automated Milk Analyzers – Integrated with Automatic Milk Collection Systems (AMCS).

Types of Milk Analyzers Available in India

1. Portable Milk Analyzers

- Best for dairy farmers and small collection centers.

- Can be used in remote villages without lab facilities.

- Some popular models include Ekomilk Ultra and Lactoscan.

2. Ultrasonic Milk Analyzers

- Works without chemicals.

- Fast and accurate results.

- Commonly used in cooperative dairy societies.

3. Infrared Milk Analyzers

- Provides high-precision testing.

- Used in large dairy plants and processing units.

4. AMCS-Integrated Milk Analyzers

- Integrated with Automatic Milk Collection Systems.

- Provides real-time data on milk quality and quantity.

Benefits of Using a Milk Analyzer in Dairy Product Quality Control

1. Improves Milk Quality & Consistency

- Ensures better product quality for consumers.

- Maintains uniformity in dairy products.

2. Reduces Adulteration & Ensures Purity

- Detects water and chemical adulteration instantly.

- Helps maintain consumer trust in dairy brands.

3. Fast & Accurate Testing for Farmers & Dairy Processors

- Reduces manual errors in milk testing.

- Provides instant, lab-quality results.

4. Helps Meet FSSAI & International Standards

- Compliance with dairy safety regulations.

- Essential for milk export approvals.

5. Increases Farmer Profits with Fair Pricing

- Ensures transparent milk pricing based on fat and SNF content.

- Encourages farmers to produce better quality milk.

Role of Milk Analyzers in Different Stages of Dairy Processing

1. At the Collection Center

- Ensures fair payment to farmers based on milk quality.

- Reduces fraud in milk collection system.

2. During Processing

- Helps dairy plants maintain consistency.

- Prevents quality degradation during production.

3. Before Packaging

- Ensures that only high-quality milk reaches consumers.

- Helps in branding and customer trust.

4. For Dairy Export Compliance

- Essential for meeting global dairy standards.

- Required for dairy exports to Europe and the Middle East.

How do Milk Analyzers Support the Automatic Milk Collection System (AMCS)?

1. What is AMCS?

- A digital system for milk collection, pricing, and testing.

- Used by dairy cooperatives like Amul, Mother Dairy, and Nandini.

2. How Milk Analyzers Integrate with AMCS

- Automatically records milk quality parameters.

- Sends real-time data to dairy processors.

- Ensures quick and transparent payment to farmers.

8. Challenges in Implementing Milk Analyzers in India

1. Cost & Affordability

- High-end analyzers can be expensive for small farmers.

2. Need for Training & Maintenance

- Farmers need training to use milk analyzers effectively.

3. Accuracy Issues in Low-Cost Analyzers

- Some cheap models may give incorrect readings.

4. Adoption in Rural Areas

- Need for government support and subsidy programs.

Conclusion: Why Milk Analyzers are Essential for Dairy Product Quality Control

Milk analyzers are no longer a luxury – they are a necessity for India’s dairy industry. From ensuring quality milk production to fair pricing and regulatory compliance, these devices are transforming dairy farming and processing. With affordable models, government support, and advancing technology, milk analyzers will continue to play a crucial role in ensuring that India remains a leader in the global dairy market.