Perforated metal sheets in this case, more visually punched, have found their way into various industries, where they have been embraced as useful materials. A well-known Chinese manufacturer, Metart Building Tech Co., specializes in the fabrication of such sheets and provides the customers with a wide selection of materials, patterns, and finishes to suit varying needs.

Understanding Perforated Sheets

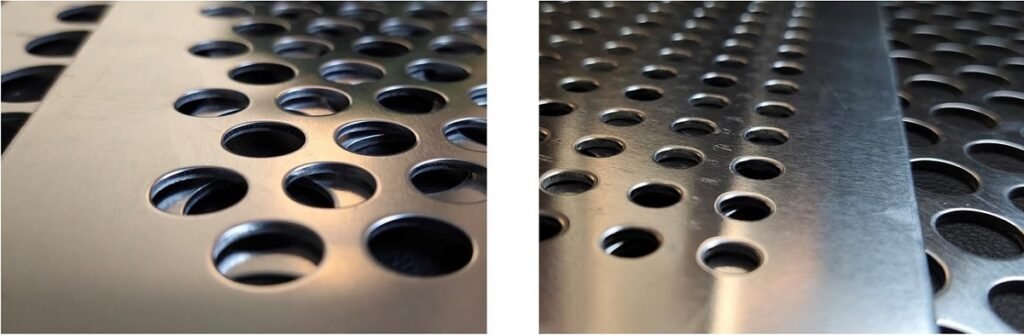

Perforated sheets, alternatively referred to as perforated metal, perforated plates or, perforated mesh, are metal sheets in which a mechanical operation of punching or stamping has been carried out to make holes. These holes may differ in diameter and shape but are evenly distributed or spaced, depending on the need. This product turns out to be structurally sound and visually appealing, hence can be used for many purposes.

Materials and Specifications

The range of perforated sheets available from Metart Building Tech is categorized into various materials depending on the use:

- Cold Rolled Mild Steel Sheets: These sheets are very strong, making them ideal for industrial applications due to their strength and toughness.

- Hot Rolled Mild Steel Sheets: These sheets are robust hence, making them ideal for heavy-duty uses.

- Pre-Galvanized Sheets: These sheets are better because of the zinc coating that makes them have greater corrosion resistance; thus, they can be used for outdoor applications.

- Aluminum Sheets: These sheets are lightweight and are easily resistant to corrosion; thus, they are suitable for architectural applications.

- Sheets of Stainless Steel SS201, SS304, SS316L: Ideal for industrial and decorative applications owing to their high corrosion resistance and high aesthetics.

- Brass and Copper Sheets: These materials are equally appealing owing to their various decorative purposes.

Thicknesses vary from 0.5mm to 20mm and common sizes of sheets are: 1000x2000mm, 1200x2000mm, 1200x2400mm, 1220x2440mm, 1250x2500mm. There are also other dimensions that may be required for a specific work.

Hole Patterns and Finishes

Metart Building Tech provides diverse hole patterns to accomplish different applications:

- Round Holes: These holes are available at 60° staggered holes , straight holes and 45° staggered holes. Round holes, however, are the common type because of their easy usage and appealing appearance.

- Square Holes: Square holes offer a different look and can be made up of straight or several dispersed holes.

- Custom Orders: Making use of CNC machines enables the company to meet the specific hole requirements that the clients may have.

Besides these alternatives, various finishing methods can be performed including, mill finish, powder coat, PVDF coating and painting which further expands aesthetic options.

Manufacturing Process

To produce perforated sheets in Metart Building Tech, there are few process steps involved:

- Material Selection: Undoubtedly, the first and most imperative step is selecting the appropriate metal sheet depending on its application.

- Punching: Some basic hole patterns are developed using punching mechanical and CNC machines.

- Finishing: application of surface treatment as a powder coat or paint for good looks and protection.

- Quality Control: Making checks of the finished products to see that all standards and requirements are met.

Applications of Perforated Sheets

There are numerous other uses of perforated sheets owing to their flexible nature:

- Architectural Design: installing perforated sheets on building facades, interior partitions and other decorative elements not only serves the purpose of aesthetics but also control the amount of air and light getting inside.

- Industrial Uses: They are used in guards over machines, in filters, and as ventilation panels in many instances where they must withstand rugged use.

- Agricultural Sector: in the equipment used for grain drying and sifting, perforated sheets are used for processing and storage of agricultural products.

- Automotive Industry: focusing on fences or ventilation, they are present in grids or other details of the pillars.

- Environmental Control: They are employed in sound-deadening boards and air cleaning units.

Customization and Innovation

Their Perforated Sheets Metart Building Tech has an edge ever since it aligned itself to strongly focus on providing them tailored solutions himself. Talking with architects or designers, the company may create original perforation patterns as well as unique and generic designs for any project. The applicability of perforated sheets is no longer limited to traditional operations directed towards creating simple punched patterns thanks to the CNC punching and laser cutting among others.

Quality Assurance

All their perforated sheets are subjected to very strict quality control procedures as they are highly compliant towards achieving industry standards while properly satisfying their clients’ specifications. The processes of choosing raw materials or the technique used for the final inspection reflect the best quality standards possible and they all serve to guarantee the quality, strength, reliability and the performance of products for all applications.

Conclusion

Metart Building Tech Co. metartbtech.com position in the market is pretty unique. They are the one-stop solution for the manufacturing of perforated sheets because they offer a variety of materials, patterns and finishes to accommodate various industries and building design styles. It is a partnership based on trust because customers know that quality is the prime value of any functional or artistic task. Metart Building Tech stands on the cutting edge of the technology advancement and is specialized in comprehensive projects handling.