According to an article on tools and services, face mill cutters are one of the essential machines used in surface precision work and polishing in modern machining. It is used to obtain surfaces with a very fine finish; it may be applied whether a designer is treatment steel, aluminum, cast iron, or any other material. Face milling is regarded as the process of choice for fast and efficient surface machining.

🔧 What Is a Face Mill Cutter?

Face mill cutters are rotational tools for CNC and manual milling machines; these tools cut radially concerning the workpiece surface. Face mills are different from end mills since the face mills cut from the side, and the end mills cut axially from the edge. These tools come with multiple replaceable inserts mounted on the cutter body and are mainly used for machining wide flat surfaces.

✅ Face Mill Cutters Features:

Multiple Cutting Edges: For faster metal removal and long tool life, it has several indexable inserts.

Wide Diameter Range: From 40 mm up to 160 mm or larger-suitable for roughing and finishing purposes.

Interchangeable Inserts: Inserts of carbide, CBN, PCD, or ceramic can be custom designed according to application material.

Optimized Chip Evacuation: Prevents clogging, ensuring smooth surface finish.

High-speed Performance: With high RPM, it gives enhanced productivity.

🏭 Applications of Face Mill Cutters:

Surface-finishing operations for larger parts

Milling of a flat surface for mold and die making

Machining of automotive, aerospace, and heavy machinery components

Slotting and side milling (with applicable inserts)

Facing operation in CNC vertical or horizontal milling machines

🛠️ Types of Face Mill Cutters:

Shell Mill Cutters

These are the heavy-duty cutters that are mounted on an arbor.

Indexable Face Mills

These mills have replaceable carbide inserts, thus minimizing tooling expenses.

High-Feed Face Mills

Very low depth but very high feed rate for enhanced metal removal rates.

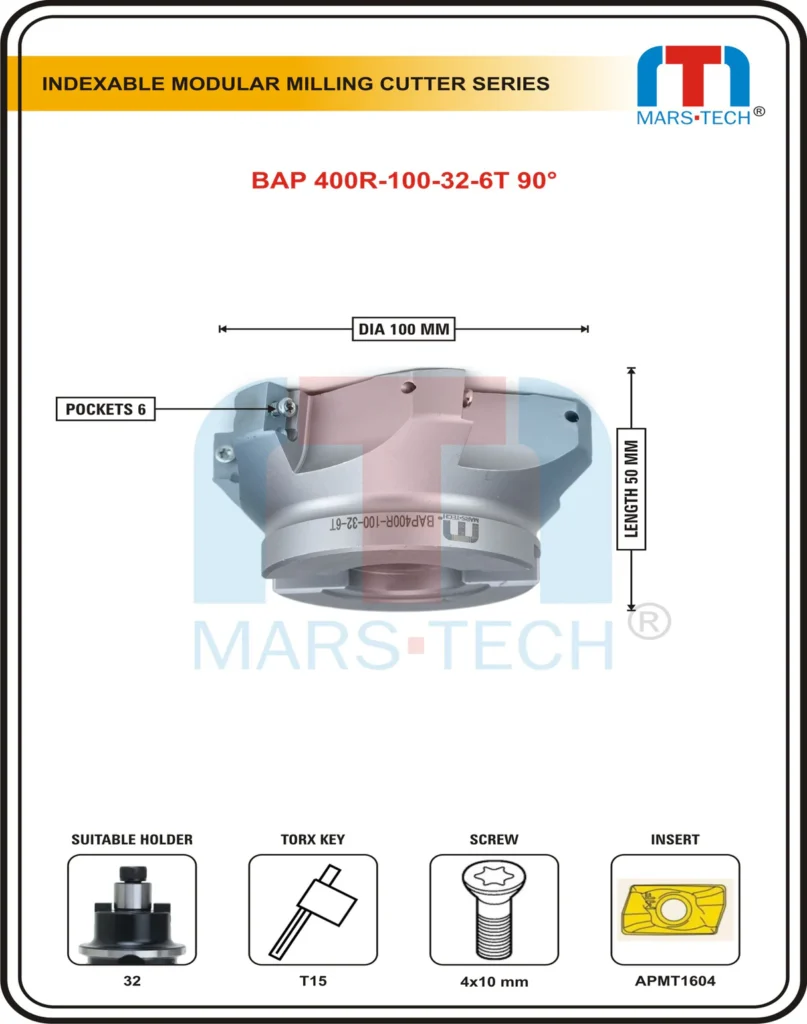

Shoulder Face Mills with 90° Arms

Perfect for both facing and shoulder milling operations in a single operation.

🔄 Insert Compatibility:

Wide varieties of inserts supported by face mills are:

RPKT/RPMT Inserts-Good for general milling on steel or stainless steel.

APKT/ADKT Inserts-Good for light-to-medium machining on aluminum and non-ferrous materials.

SEKN/SNMG Inserts-Good for cast iron and roughing applications.

⚙️ Material-Specific Face Milling:

Material Type Recommended Insert Type Surface Speed (m/min)

Mild Steel Coated Carbide 200-300

Stainless Steel Cermet or PVD Coated 120-180

Cast Iron Uncoated Carbide 180-250

Aluminum Alloys PCD or Uncoated Carbide 600-1000

🎯 Advantages of Using Quality Face Mill Cutters:

Better surface finish and flatness

Higher material removal rates

Reduced the cost of operations due to the use of replaceable inserts

Longer tool-life

Machining versatility over different platforms and materials

💡 Face Milling Tips:

Regularly check insert wear and change dull edges to maintain finish quality.

Always use coolant for materials that create high temperatures, such as stainless steel.

Feed rate and depth of cut should always be according to the instructions given by the insert manufacturer.

Balance the cutter and check for run-out to eliminate vibration at high speeds.

📌 Conclusion:

Face mill cutters are a necessity for any precision machining policy. Their ability to provide consistent, high-quality flat surfaces at high speed is what gives them an edge in workshops, CNC operations, and the mass production sector. From facing steel to finishing aluminum dies, a combination of a suitable face mill cutter and the right inserts can greatly enhance your machining performance.

❓ Frequently Asked Questions

Q1. What is the difference between face and end milling?

A: Material is removed from a surface using radial cuts of multiple inserts in face milling, whereas it is axial cuts are used mainly for slots and cavities in end milling.

Q2: Which materials can be machined using face mill cutters?

A: Face mill cutters can machine various materials, including mild steel, stainless steel, aluminum, cast iron, and many others, depending on the chosen inserts.

Q3. Can face mill cutters be used on vertical milling machines?

A: Yes, face mill cutters find extensive applications on both vertical and horizontal milling machines, of course, depending on the setup and size of the component.

Q4. How do I choose a proper face mill cutter?

A: It involves looking into the type of material, desired surface finish, cutting speed, and machine compatibility; select both the cutter body and inserts according to your operation.

Q5. What is the diameter of face mill cutters?

A: The diameter of face mill cutters commonly ranges from 40mm to 160 mm, though larger diameters could be available for specific needs in industrial applications.