Milling cutters are integral devices in the field of manufacturing, used for accurate profiling and cutting of different materials like metals, such as aluminum, plastics, and wood. It does not matter if you have a manual or CNC milling machine; the type and quality of milling cutter you choose determine how efficiently, accurately, and in what finish you can complete your workpiece.

A milling cutter is a rotary tool used in milling machines and machining centers capable of removing material from a workpiece. These tools have linear cutting edges (often termed “teeth’) which rotate as the precise milling operation takes place and therefore gradually remove materials by moving into the workpiece.

Different shapes feature end mills– different cuts will sometimes necessitate going out slightly under the ends of some parts–therefore, the mill may come in different sizes and materials for certain milling action and cutting.

Types of milling cutters

There are various kinds of milling cutters in existence, and thus knowledge of their classification would give an appreciation of the most suitable cutter for the application.

- End Mill Cutters

These are the most popular types and are used for profile, tracer, face, and plunge milling with tips that can be flat, ball nose, or corner radius.

- Face Mill Cutters

These cutters are designed for high-speed milling of large flat surfaces. They will consist of numerous ends on a rotating body.

- Slab Mill Cutters

If heavy material removal over a large surface area is required, then these slab cutters should be used. They have a wide cut and are normally used in a horizontal mill.

- Side and Face Cutters

Side Face Cutters are used to mill slots and grooves having teeth on both sides and the circumference.

- Shell Mill Cutters

Shell mills are large-diameter tools that accept multiple indexable inserts and are used in face and contour milling.

- Fly Cutters

These are single-point cutting tools used for generating flat surfaces. These tools are simple, cost-effective substitutes for machining flat surfaces over large areas.

- T-Slot Cutters

Designed specifically for T-shaped slots in machine tool tables or parts.

- Gear Cutters

Used for making gear teeth by cutting the workpiece with successive passes.

Materials of Milling Cutters

High-Speed Steel (HSS): Economical; sharpens easily.

Carbide: Higher cutting speeds and wear resistance.

Cobalt Steel: Good performance at high temperatures.

Ceramics and Diamond-Coated Cutters: For high-speed and high-precision use.

Key Features of Milling Cutters

Cutting Edge Geometry: Influences chip-removal rates and surface finish.

Number of Flutes: Affects chip removal and cutting speed.

Coating: TiN, TiAlN, or DLC improves wear resistance.

Shank Type: Straight or tapered, depending on the machine compatibility.

Applications of Milling Cutters

Manufacturing Automotive Components,

Machining of Aerospace Components,

Mould and Die manufacturing,

Shaping Wood and Plastic,

Slotting, Contouring, and Pocketing Operations.

Benefits of Using the Right Milling Cutters

Enhanced surface finish

Improved tool life

Increased material removal rate

Reduced machining time

Better dimensional accuracy.

Milling cutter maintenance tips

Always inspect cutters for wear before use.

Use proper coolant to reduce heat generation.

Ensure correct feed rate and spindle speed.

Regularly regrind tools for long life.

Store cutters in a dry and clean environment.

Popular Brands of Milling Cutters in India

Sandvik Coromant

Mitsubishi

YG-1

Jaibros

Kennametal

Widia

ISCAR

Frequently Asked Questions

Q1. What is the difference between an end mill and a face mill?

An end mill is intended for peripheral and plunge cutting, while a face mill is meant to be used for cutting flat surfaces with the aid of multiple cutting edges.

Q2. How do I pick the right milling cutter?

Materials, roughing or finishing (operation type), compatibility with the machine, and geometry of the tool need to be considered.

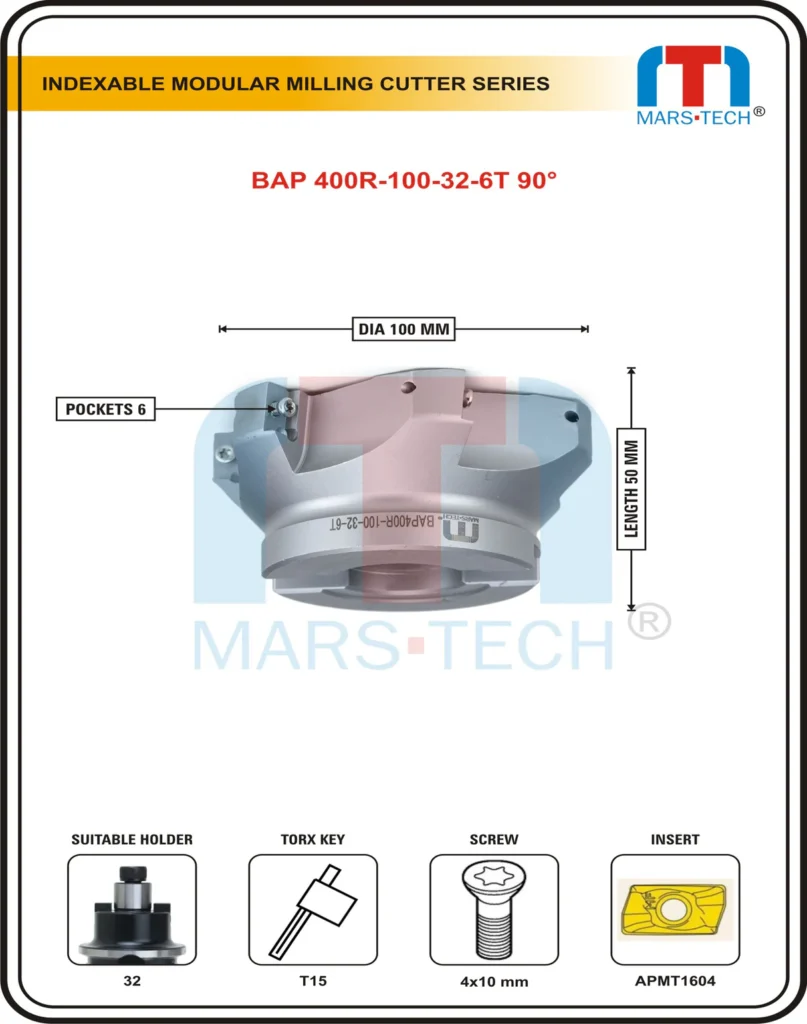

Q3. What do you mean by “indexable milling cutters”?

It means this type of cutter possesses replaceable inserts that can be easily rotated or flipped once worn, thus economizing cost for high-volume operations.

Q4. Do milling cutters undergo resharpening?

Yes. Almost all HSS and carbide cutters can be resharpened, and doing so prolongs tool life as well as preserves cutting efficiency.

Q5.What is the most desirable number of flutes in a milling cutter?

Fewer flutes (2 to 3) are the most desirable ones for softer materials like aluminum, while more flutes (4 or greater) are used for tougher materials like steel.

Q6. How does coating affect cutter operations during milling?

The coatings reduce friction, stop chips from sticking, have a higher heat tolerance or resistance, and foremost, extend the life of the tool.

Conclusion

Choosing the right milling cutter is very important to achieving precision, ensuring productivity, and surface quality in machining processes. The availability of a wide variety in types and materials is there to satisfy application requirements. From a small workshop to a huge mass production unit, the right cutter will increase productivity while minimizing costs.