When it comes to overhead cranes, the integrity of crane rails is vital to operational safety and efficiency. Over time, even the most robust systems are susceptible to wear and damage. That’s why Inspeccion De Rieles (rail inspection) is not just a maintenance task—it’s a critical investment in your equipment’s performance and safety.

At Dorance, we specialize in the manufacturing, assembly, and maintenance of rail systems for overhead cranes, railroads, and heavy industrial transport systems. With over 7,600 meters of crane railways and 60 kilometers of railroad systems installed across South America, our track record speaks for itself.

In this post, we’ll explore the most common overhead crane rail defects, how to identify them, and how Inspeccion De Rieles can prevent costly downtimes and safety incidents.

- Rail Cracks: The Silent Threat

Cracks are among the most dangerous defects in crane rail systems. They typically appear in high-stress areas—particularly near joints, under welds, or around clip fasteners.

How to Identify:

- Visual inspection may reveal surface cracks or hairline fractures.

- Ultrasonic testing (UT) helps detect internal or sub-surface cracks that are invisible to the naked eye.

- Increased noise or vibrations during crane movement can be a symptom.

We conduct thorough Inspeccion De Rieles using both traditional and advanced non-destructive methods to ensure no defect goes undetected. Our welding solutions, including aluminothermic welding, eliminate impact zones in the rail and prevent crack formation.

- Corrugation: The Wavy Menace

Rail corrugation refers to irregular wear patterns that result in a wave-like surface on the rail head. This defect leads to increased vibrations, noise, and accelerated wear on both the rail and crane wheels.

Causes:

- Repeated rolling under heavy loads

- Misalignment of rails or uneven distribution of load

- Inadequate rail hardness or improper installation

How to Identify:

- Audible humming or vibration during crane operation

- Visual inspection shows wavy or uneven wear

- Increased maintenance frequency on crane wheels

We use rail grades with tensile strength from 680 to 1100 N/mm² and precise assembly methods that minimize the risk of such defects. We also perform preventive Inspeccion De Rieles to catch early signs before they escalate.

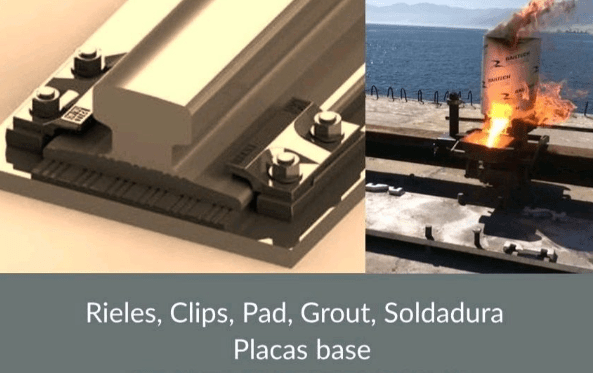

- Loose or Damaged Fastening Systems

Fasteners—like clips, pads, and base plates—play a critical role in stabilizing rails. Damaged or loose components can lead to track misalignment and rail movement, ultimately causing derailment or mechanical failure.

How to Identify:

- Audible clicking or clanking sounds during crane motion

- Rails appear loose or shift under load

- Uneven wear on one side of the rail head

We supply and install high-capacity clips (50kN to 200kN) and oil-resistant pads. Our fastening systems are designed for extreme industrial conditions and installed with precision to ensure long-term reliability.

- Joint Misalignment and Impact Zones

Poorly aligned joints or improperly welded rails can cause impact zones, which stress the wheels, bearings, and electrical systems of overhead cranes.

Symptoms:

- Bumps or jolts during crane travel

- Premature wear on wheels

- Sudden stops or equipment error codes

Our aluminothermic welding process ensures smooth transitions across joints, extending the life of the entire crane system. We offer complete welding services under subsidiary DRS (Dorance Runway Services), which also handles inspections, engineering, and preventive maintenance.

- Rail Wear and Profile Deformation

Over time, the rail head can wear down due to constant wheel contact, especially if the crane is heavily loaded or frequently used. Profile deformation affects alignment, traction, and operational efficiency.

How to Identify:

- Measurable loss of metal on rail head

- Asymmetrical wear patterns

- Crane misalignment or tracking issues

During our Inspeccion De Rieles, we evaluate rail profile and wear depth, helping our clients decide whether resurfacing, replacement, or realignment is necessary.

Why Inspeccion De Rieles Is Essential

Routine Inspeccion De Rieles helps avoid:

- Unexpected shutdowns due to catastrophic failure

- Increased maintenance costs on cranes

- Safety risks for personnel

- Damage to valuable cargo or infrastructure

Preventive inspection not only keeps your system compliant with safety regulations—it also extends the service life of your crane system and reduces total cost of ownership.

Why We are the Best Choice

With successful projects across Colombia, Ecuador, Peru, Chile, and Panama, we are the preferred provider of overhead crane rail systems for steel plants, seaports, cement factories, and mining operations. Here’s what sets us apart:

- Full-Service Expertise

From design and engineering to installation and maintenance, we offer turnkey solutions. Our services include:

- Rail supply, assembly, and welding

- Runway system inspections and repairs

- Aluminothermic welding and thermite kits

- High-performance fastening systems

- Proven Performance

- +7,600 meters of crane railways installed

- +800 welds with 0 reported defects

- Projects completed in record time with 0 accidents

- European-Backed Standards

We partner with top European rail manufacturers, ensuring that all materials meet or exceed international standards. We supply rail types DIN, ASCE, CR, and more—with tensile strengths up to 1100 N/mm².

- Local Knowledge, Global Vision

We understand the challenges of operating in diverse industrial environments across Latin America. Our bilingual teams and tailored solutions make us the go-to choice for companies looking to optimize their Inspeccion De Rieles and crane runway systems.

Crane rail systems are the backbone of heavy industrial operations, and any defect—whether it’s a crack, corrugation, or misalignment—can lead to serious consequences. Regular Inspeccion De Rieles is the key to spotting these issues early and avoiding unexpected costs and hazards.

With us, you’re not just getting a service provider—you’re gaining a strategic partner with the experience, tools, and commitment to excellence that your operation deserves.

Let’s build something that lasts. Choose Dorance.

FAQs

- What are common crane rail defects?

Cracks, corrugation (wavy wear), loose fasteners, misaligned joints, and head wear are the most common defects.

- How do I know if my crane rail needs inspection?

Unusual noises, vibrations, uneven wheel wear, or crane misalignment are clear signs you need an Inspeccion De Rieles.

- Why choose you for rail inspection services?

We offer expert-level inspections, certified welding, and complete rail system solutions—with proven safety and zero weld defects.

- How often should crane rails be inspected?

Basic inspections should be done monthly, with detailed inspections and testing every 6 to 12 months depending on use.