In modern construction, selecting the right materials is a crucial decision that impacts the strength, durability, and overall cost of a project. Among the various materials available, SS Weld Mesh stands out as a reliable, versatile, and cost-effective solution that is gaining popularity among professionals. Known for its exceptional strength, corrosion resistance, and ease of installation, SS Weld Mesh offers numerous advantages in construction, making it an essential material for a wide range of applications.

In this article, we’ll dive deep into the top 5 construction advantages of using SS Weld Mesh and why it is the preferred choice for builders, architects, and engineers around the world.

What Is SS Weld Mesh?

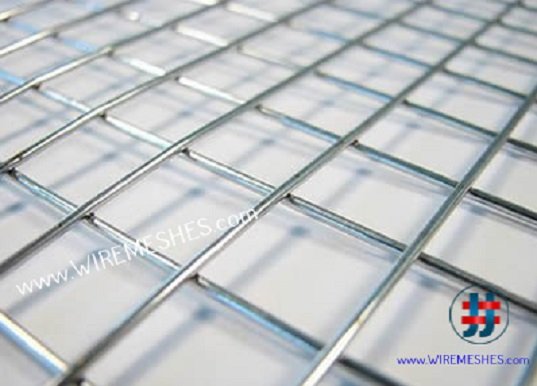

Before diving into the advantages of SS Weld Mesh, it’s important to understand what it is and why it’s so effective in construction. SS Weld Mesh refers to stainless steel wire mesh that is created by welding stainless steel wires together at their intersections. This welding process creates a grid-like structure that is extremely durable and capable of handling significant weight and pressure. The mesh is available in various wire gauges, mesh sizes, and patterns, making it versatile for different construction needs.

The primary material, stainless steel, is known for its high resistance to corrosion, which makes SS Weld Mesh a popular choice for applications in harsh environments where other materials would degrade over time. This is why it is commonly used in projects where durability and long-term performance are critical.

Common Applications of SS Weld Mesh in Construction:

- Reinforcement: It’s widely used to reinforce concrete structures like slabs, foundations, and walls.

- Fencing: Perfect for creating durable and secure barriers in industrial, residential, and commercial projects.

- Partitions: Used for dividing spaces in warehouses, factories, and construction sites.

- Architectural Features: Employed in decorative designs for facades and other visual elements.

With such versatility, SS Weld Mesh has proven itself as a vital component in modern construction projects, ensuring safety, stability, and sustainability.

Why Choose SS Weld Mesh for Construction?

The decision to incorporate SS Weld Mesh in construction projects is often driven by its unique combination of strength, durability, and adaptability. Here’s why it’s considered an essential material in today’s construction world:

- Strength and Stability: SS Weld Mesh is made from stainless steel, a material known for its high strength-to-weight ratio. The welded design provides uniformity and rigidity, making it capable of handling heavy loads and preventing deformations.

- Corrosion Resistance: Unlike other materials, SS Weld Mesh doesn’t rust or corrode, even when exposed to moisture, chemicals, or extreme weather conditions. This is especially important in coastal areas or places with high humidity.

- Flexibility and Customization: The mesh comes in various thicknesses, wire gauges, and mesh patterns, allowing builders to choose the right specifications for each project’s requirements.

Whether you’re reinforcing concrete, building fences, or creating structural components, SS Weld Mesh offers superior performance and reliability.

Top 5 Construction Advantages of SS Weld Mesh

There are numerous reasons why SS Weld Mesh is highly valued in the construction industry. Below are the top five construction advantages that make it a go-to material for many builders and contractors .

1. Durability and Longevity

One of the standout features of SS Weld Mesh is its exceptional durability. The stainless steel composition provides excellent resistance to corrosion, rust, and wear and tear, ensuring that structures reinforced with this material last longer and perform better over time.

Why Durability Matters:

- Less Maintenance: Structures reinforced with SS Weld Mesh require significantly less maintenance than those using traditional materials like iron or steel, which are prone to rusting and corrosion over time.

- Cost-Effective in the Long Run: While the initial investment in SS Weld Mesh may be higher than other materials, the long-term cost savings due to its durability and reduced maintenance requirements make it a smart investment.

For example, a bridge constructed using SS Weld Mesh will have a longer lifespan compared to one reinforced with traditional materials like mild steel, which might require frequent repairs and replacements due to rust and degradation.

2. Superior Strength and Stability

Another significant advantage of SS Weld Mesh is its strength and stability. The welded design of the mesh creates a robust framework that is capable of supporting heavy loads without buckling or warping. This makes it an ideal reinforcement material for high-stress applications.

Key Benefits of Superior Strength:

- Load-Bearing Capacity: SS Weld Mesh can support large amounts of weight without bending or breaking, which is critical in construction projects like high-rise buildings, bridges, and large industrial structures.

- Even Distribution of Pressure: The uniform grid structure of SS Weld Mesh allows for an even distribution of weight and pressure, minimizing the risk of cracks or failures in reinforced concrete.

Whether used in foundation slabs, reinforced walls, or structural beams, SS Weld Mesh ensures that the overall stability of the structure is maintained under significant pressure and weight.

3. Ease of Installation

Construction projects often face tight timelines and budgets, which makes time-efficient installation a crucial factor. SS Weld Mesh comes in pre-fabricated sheets or rolls that can be quickly installed without the need for welding on-site. This significantly reduces the labor time and complexity involved in the reinforcement process.

How SS Weld Mesh Saves Time:

- Pre-Welded Sheets and Rolls: The mesh is available in ready-to-use sheets or rolls, which can be easily cut and shaped to fit the required dimensions.

- No On-Site Welding Required: Unlike traditional reinforcement methods, which require welding at the construction site, SS Weld Mesh is ready to be placed directly, reducing the need for specialized labor.

- Quicker Project Turnaround: The fast installation process helps shorten construction timelines, allowing projects to be completed more efficiently and cost-effectively.

For large-scale projects, such as the construction of warehouses or industrial facilities, SS Weld Mesh offers significant time savings, which can directly impact project delivery and overall costs.

4. Cost-Effectiveness Over Time

While SS Weld Mesh may initially seem like a more expensive option compared to traditional reinforcement materials, it offers long-term cost savings due to its durability and low maintenance requirements.

Cost Advantages of SS Weld Mesh:

- Lower Maintenance Costs: SS Weld Mesh is corrosion-resistant and highly durable, meaning it doesn’t need frequent repairs or replacements, which translates to reduced long-term maintenance costs.

- Longevity: Structures reinforced with [SS Weld Mesh] tend to last much longer than those using traditional materials, further reducing the overall cost of ownership.

- Reduced Labor Costs: The ease of installation and pre-fabrication of SS Weld Mesh reduce the need for skilled labor and on-site adjustments, cutting down on construction expenses.

In many cases, the higher initial cost is outweighed by the significant savings in maintenance and labor, making SS Weld Mesh a cost-effective solution in the long run.

5. Eco-Friendly and Sustainable

Sustainability is an increasingly important factor in modern construction, and SS Weld Mesh fits perfectly into eco-conscious building practices. Stainless steel is 100% recyclable, making it an environmentally friendly choice that can be reused at the end of its life cycle.

Environmental Benefits of SS Weld Mesh:

- Recyclability: Stainless steel is highly recyclable, helping to reduce waste and the need for virgin raw materials.

- Lower Carbon Footprint: The production of stainless steel has a lower environmental impact compared to other materials like aluminum or plastic, making it a greener choice for construction projects.

- Sustainable Building Practices: Using SS Weld Mesh supports green building initiatives and can contribute to achieving sustainability certifications like LEED (Leadership in Energy and Environmental Design).

In addition to its performance benefits, SS Weld Mesh helps builders meet sustainability goals and minimize the environmental footprint of their projects.

How to Choose the Right SS Weld Mesh for Your Project

Choosing the right type of SS Weld Mesh is crucial for ensuring that your project meets its specific needs. Here are some key factors to consider:

- Mesh Size and Thickness: Different applications require different mesh sizes and wire thicknesses. Choose a mesh that meets the load-bearing requirements of your project.

- Stainless Steel Grade: Depending on the environment where the mesh will be used, you may need to select a specific grade of stainless steel. For example, marine-grade stainless steel is recommended for coastal areas.

- Supplier Quality: Ensure that you work with reliable suppliers who provide high-quality SS Weld Mesh that meets industry standards.

For the best results, it’s always a good idea to consult with experts to select the right SS Weld Mesh specifications for your project.

Real-Life Examples of SS Weld Mesh in Construction

To further illustrate the benefits of SS Weld Mesh, consider the following real-world applications:

- High-Rise Buildings: SS Weld Mesh is used to reinforce the concrete in skyscrapers, ensuring the structure can handle heavy loads while maintaining stability over time.

- Bridges and Overpasses: The strength and durability of SS Weld Mesh make it ideal for bridges that are subjected to constant weight and environmental stress.

- Fencing for Industrial Sites: SS Weld Mesh provides secure, long-lasting fencing for industrial and commercial sites, offering protection against unauthorized access and harsh weather conditions.