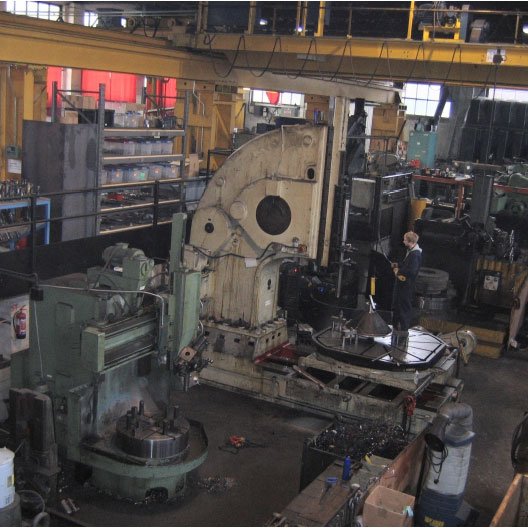

Centrifuges are essential for production activities in various industries, including healthcare, research, and manufacturing. Like any mechanical equipment, they can encounter issues that disrupt their performance. What are the most common Centrifuge Issues, and how should you deal with them?

Overheating in Centrifuges

Overheating is among the most common Centrifuge Issues, particularly in high-use environments like laboratories or industrial settings. Some signs that it is overheating include when it feels abnormally hot to the touch, the machine automatically shuts down, or the delicate electronic parts may malfunction. The overheating could be due to a number of reasons, including:

- Poor machine ventilation

- A malfunctioning cooling fan

- A centrifuge operation beyond the recommended limit

Overheating of this critical machine should be addressed immediately. First, ensure the machine is in a well-ventilated area with ample space and adhere to the recommended operating cycles. Also, clean the cooling fan and air vents, or replace them if they are no longer efficient.

Leakage of Samples in Centrifuges

Sample leakage as the centrifuge operates is another issue that could lead to problems such as contamination, equipment damage, and inaccurate results. The leakage begins with visible spillage before causing rattling noises when it gets to the rotor. Some reasons that could lead to the leakage include an issue with the seal tubes and rotor imbalance.

Implementing the right fixes involves addressing both immediate symptoms and underlying causes to restore the functionality of the Used Centrifuge. The first remedy is investment in centrifuge tubes specifically designed for the equipment. If rotor gaskets are worn out, replacement of these parts is the best remedy.

Failure to Reach Target Speed

The performance of this machine depends on its ability to attain and maintain a given speed (RPM). Failure to reach this RPM could be due to issues such as poor drive motor lubrication, unstable power supply, or worn-out bearings. These issues contribute to the overall inefficiency of the centrifuge.

Periodic maintenance checks for the motor, bearings, and power supply connections can help to keep the Used Centrifuge in top shape. For older buildings with outdated electrical systems, consider upgrading the infrastructure to provide reliable power for this sensitive equipment. Additionally, calibrate the centrifuge periodically to ensure accurate speed settings.

Strange Noises from the Machine

While the machine is expected to produce some noise as it operates, unusual noises could signify a mechanical issue that should be dealt with immediately. A persistent grinding noise often indicates friction between moving parts, typically resulting from worn-out bearings or insufficient lubrication. A whining sound could be from misaligned or degraded bearings. Rattling may indicate small debris inside the rotor chamber or loose screws and bolts.

Proper and regular lubrication could help with these Centrifuge Issues. If the problem persists, it could be time to inspect the rotor for signs of cracks, deformations, or worn edges. For significant rotor damage, replace it to ensure safety and performance. Additionally, inspect the centrifuge for any debris and tighten all the loose parts.

Imbalance in the Rotor

Another issue that calls for immediate Centrifuge Repair is rotor imbalance. This imbalance could cause excessive vibrations, unusual noises, and premature cycle termination. It could be because of uneven sample loading or a damaged rotor.

A rotor inspection to identify and deal with the signs of damage could help the situation. For imbalance that comes from uneven sample loading, use a precise digital scale to measure the weight of each sample, including the tube and its contents.

Conclusion

Addressing centrifuge problems promptly ensures efficient and uninterrupted operations. Additionally, it extends the lifespan of the equipment. The issues that may require Centrifuge Repair range from overheating to rotor imbalance. Regular maintenance and adherence to operating guidelines are key to minimizing downtime and achieving optimal performance.

Centrifuge machines play a pivotal role in a variety of industries, from chemical manufacturing to wastewater treatment. These high-speed machines are essential for separating substances of varying densities, making them indispensable to operations. However, as with any complex machinery, centrifuges are prone to issues that can impact their performance, lifespan, and overall efficiency.

Thanks

Guest-post.org