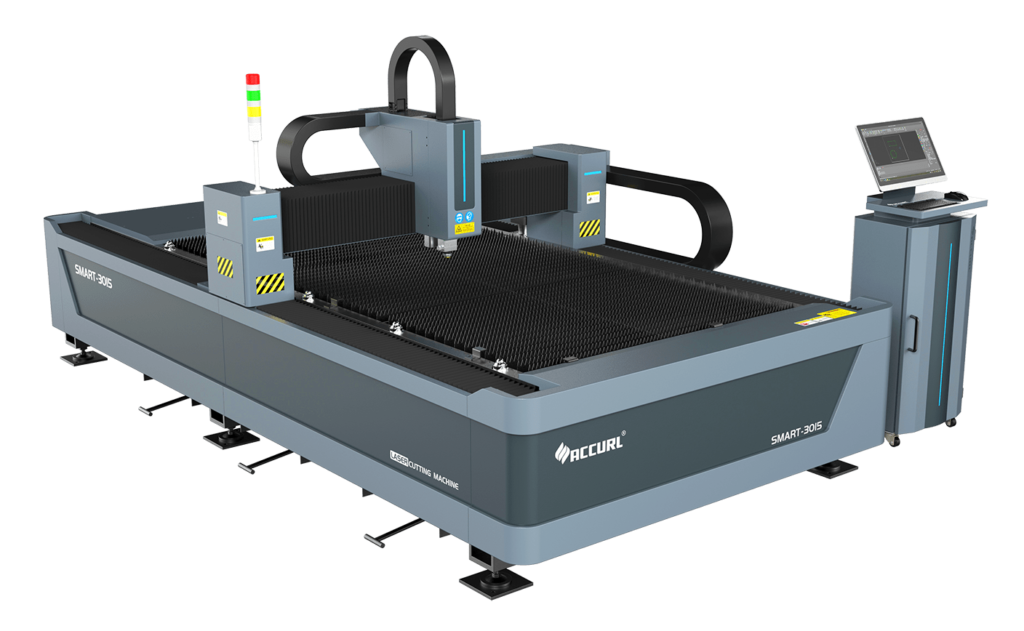

In today’s fast-paced manufacturing world, precision and efficiency are everything. The introduction of fiber laser cutting machine has been a revolutionary step forward in industries that require clean, accurate cuts. This advanced technology uses laser beams to slice through materials with incredible precision, providing manufacturers with unparalleled control over their production processes. With its unmatched speed, flexibility, and precision, the fiber laser cutting machine is quickly becoming an essential tool in various industries.

Fiber laser cutting machines work by directing a highly focused laser beam onto a material, typically metal, which melts, burns, or vaporizes, resulting in a clean cut. The key advantage of these machines lies in the use of fiber optics to deliver the laser, providing superior energy efficiency and precision. This innovative technology is changing the game for industries from automotive to aerospace, offering faster, cleaner, and more cost-effective cutting solutions.

Precision Like Never Before with Fiber Laser Cutting Machines

One of the most remarkable features of fiber laser cutting machines is their precision. Unlike traditional cutting methods, such as plasma or water jet cutting, fiber laser cutting provides incredibly fine tolerances. This means that manufacturers can achieve cuts with extremely tight margins, reducing the need for secondary processes like grinding or polishing. Whether working with thin sheets of metal or thicker, more robust materials, fiber laser cutting machines ensure that every cut is sharp, clean, and precise.

The ability to produce intricate designs without compromising on quality has made the fiber laser cutting machine a preferred choice for industries where accuracy is critical. From creating complex shapes to intricate patterns, this cutting technology ensures a high level of consistency and repeatability, allowing businesses to meet demanding specifications with ease.

Speed and Efficiency: Fiber Laser Cutting Machines in Action

Speed is another area where fiber laser cutting machines excel. Their cutting process is significantly faster than traditional methods, which not only boosts productivity but also reduces operating costs. In industries where time is money, fiber laser cutting machines allow manufacturers to complete jobs in a fraction of the time it would take with older technology. This increase in efficiency means that businesses can produce more items in less time, increasing their overall output.

Fiber laser cutting machines are particularly effective for high-volume production runs, as they can handle large quantities of parts in a short period. Additionally, these machines require less maintenance compared to other cutting technologies, leading to less downtime and more uptime. With reduced maintenance needs and faster cutting times, fiber laser cutting machines provide manufacturers with a higher return on investment.

Versatility Across Materials with Fiber Laser Cutting Machines

Another key advantage of fiber laser cutting machines is their versatility. Unlike some cutting technologies that are limited to specific materials, fiber lasers can cut through a wide variety of materials, including metals like steel, aluminum, and brass, as well as plastics and composites. This makes them an ideal choice for industries that work with diverse materials, such as automotive, aerospace, and electronics.

The flexibility of fiber laser cutting machines also extends to the thickness of materials. Whether you’re working with thin sheets of metal or thicker plates, fiber laser cutting machines can adapt to different material thicknesses, offering consistent performance and precise cuts across a range of projects. This versatility allows manufacturers to streamline their production processes, using one machine for multiple types of jobs.

Why Fiber Laser Cutting Machines Are the Future of Manufacturing

The future of manufacturing is here, and it’s being driven by the capabilities of fiber laser cutting machines. With their combination of speed, precision, and versatility, fiber laser cutting machines are helping companies stay competitive in an increasingly globalized market. These machines provide businesses with the tools they need to create complex designs, reduce waste, and increase production efficiency.

Fiber laser cutting technology is continuously evolving, with improvements in power output, cutting speed, and material compatibility. As these machines become even more advanced, industries can expect even greater levels of precision and efficiency. Manufacturers will be able to cut faster, more accurately, and with fewer resources, further enhancing their overall productivity.

Moreover, fiber laser cutting machines are also becoming more accessible to small and medium-sized businesses, thanks to advancements in technology and reduced costs. This democratization of cutting-edge technology means that even smaller manufacturers can now benefit from the advantages of fiber laser cutting, leveling the playing field and encouraging innovation across industries.

Conclusion: Embrace the Power of Fiber Laser Cutting Machines

Fiber laser cutting machine are more than just a trend—they represent the future of precision manufacturing. By providing manufacturers with unmatched accuracy, speed, and material versatility, these machines are setting new standards in the industry. Whether you’re looking to streamline your production processes, improve quality, or reduce costs, a fiber laser cutting machine is the solution to take your operations to the next level.

As industries continue to evolve, so too will the technology behind fiber laser cutting machines. For businesses aiming to stay ahead of the curve, embracing this advanced cutting technology is not just an option—it’s a necessity. With fiber laser cutting machines, you’re not just investing in a tool; you’re investing in the future of manufacturing.