In today’s manufacturing world, precision, speed, and cost-efficiency are paramount. Custom CNC turning services have become the backbone of modern machining, offering unmatched accuracy and adaptability for various industries. Whether you’re producing prototypes or large-scale production runs, these services ensure exceptional quality and performance.

This article explores how businesses can benefit from Custom CNC turning services, why partnering with the right CNC turning company is crucial, and how specialized services like aluminum CNC turning services and CNC lathe machining services deliver superior custom CNC turned parts.

Understanding Custom CNC Turning Services

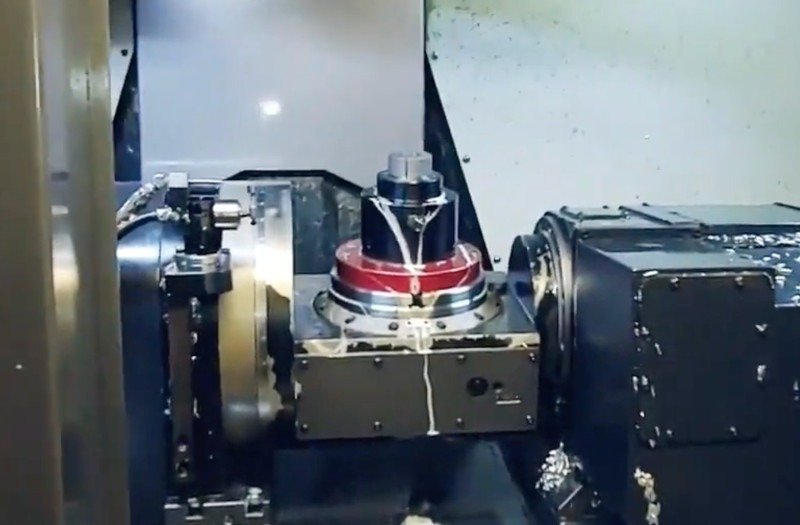

Custom CNC turning services involve using automated, computer-controlled lathes to create precise cylindrical components. Unlike traditional machining, CNC turning allows manufacturers to achieve tighter tolerances, reduce errors, and boost productivity.

Industries such as automotive, aerospace, medical, and electronics rely heavily on CNC turning because of its ability to deliver custom CNC turned parts that meet exact specifications. By leveraging advanced technology, Custom CNC turning services offer:

-

High accuracy and repeatability for consistent quality.

-

Faster production times with minimal manual intervention.

-

Cost-effective solutions for both small and large batch manufacturing.

Why Partner with a CNC Turning Company?

Choosing the right CNC turning company is vital for businesses that demand precision. A reliable partner offers advanced machinery, skilled technicians, and streamlined processes to deliver custom CNC turned parts efficiently.

Key benefits of working with a professional CNC turning company include:

1. Access to Advanced Equipment

Modern CNC machines ensure high-speed production while maintaining exceptional precision.

2. Expertise in Material Selection

From stainless steel to titanium and especially aluminum, expert machinists recommend the right materials for specific needs.

3. Quality Assurance

Top CNC turning companies implement strict quality control measures, ensuring every part meets industry standards.

By leveraging the experience of a seasoned CNC turning company, businesses can reduce waste, minimize costs, and ensure reliable outcomes for their projects.

The Role of Aluminum CNC Turning Services

Lightweight, corrosion-resistant, and durable, aluminum remains one of the most commonly used materials in CNC machining. Aluminum CNC turning services specialize in creating high-precision parts used in industries like automotive, aerospace, and electronics.

Benefits of aluminum CNC turning services include:

-

Excellent strength-to-weight ratio, making components lighter yet robust.

-

Superior machinability, reducing production time and cost.

-

Versatility, enabling the production of intricate shapes and designs.

Businesses relying on Custom CNC turning services often prefer aluminum for projects requiring custom CNC turned parts that balance durability with lightweight properties.

CNC Lathe Machining Services: Enhancing Precision

Another critical element of Custom CNC turning services is CNC lathe machining services. These services use specialized lathes to shape raw materials into exact dimensions, creating components with exceptional detail.

Applications of CNC Lathe Machining Services

-

Automotive components like shafts and bushings.

-

Aerospace parts requiring high accuracy.

-

Medical devices that demand precision machining.

By incorporating CNC lathe machining services within Custom CNC turning services, manufacturers achieve a higher level of precision in crafting custom CNC turned parts, even for complex geometries.

Custom CNC Turned Parts: Tailored for Every Industry

The demand for custom CNC turned parts has grown significantly as industries seek specialized solutions. Whether it’s small prototypes or bulk manufacturing, Custom CNC turning services ensure every component is produced to exact client specifications.

Industries benefiting from custom CNC turned parts include:

-

Aerospace: High-tolerance components for aircraft systems.

-

Automotive: Engine parts and precision fittings.

-

Medical: Surgical tools and device components.

-

Electronics: Miniature connectors and housings.

How Custom CNC Turning Services Improve Efficiency

Businesses are constantly under pressure to reduce costs while improving quality. Custom CNC turning services streamline manufacturing by automating processes, minimizing waste, and increasing throughput.

Advantages of Efficiency-Driven CNC Turning

-

Shorter Lead Times – Rapid turnaround for time-sensitive projects.

-

Reduced Manual Errors – Automation ensures greater accuracy.

-

Cost Savings – Fewer mistakes and reduced scrap material.

By combining CNC lathe machining services and aluminum CNC turning services, manufacturers ensure that custom CNC turned parts meet stringent industry requirements without compromising on cost or quality.

The Future of Custom CNC Turning Services

The future of Custom CNC turning services is promising, driven by advancements in technology like AI-driven programming and improved tooling. As industries evolve, the need for high-precision custom CNC turned parts will continue to rise.

Key trends include:

-

Integration of automation and robotics to further reduce human intervention.

-

Use of advanced materials for lighter and stronger components.

-

Smart manufacturing using IoT-enabled CNC machines for real-time monitoring.

These innovations make Custom CNC turning services indispensable for manufacturers aiming to stay competitive.

Why Choose Zintilon for Your CNC Turning Needs?

Zintilon provides comprehensive Custom CNC turning services, ensuring precision-engineered components for various industries. With expertise in CNC lathe machining services, aluminum CNC turning services, and delivering high-quality custom CNC turned parts, Zintilon focuses on:

-

State-of-the-art machinery for superior accuracy.

-

Skilled professionals with deep industry knowledge.

-

Commitment to quality control at every production stage.

Partnering with Zintilon ensures that your business benefits from reliable, high-performance CNC solutions designed to meet your unique requirements.

Conclusion

In a competitive manufacturing landscape, Custom CNC turning services have become essential for producing precise, durable, and cost-efficient components. Whether it’s through aluminum CNC turning services, CNC lathe machining services, or sourcing custom CNC turned parts from a trusted CNC turning company, businesses gain the advantage of accuracy, speed, and quality.

By embracing modern machining technologies, companies can streamline production, enhance performance, and meet the growing demand for precision-engineered parts—making Custom CNC turning services a cornerstone of industrial success.