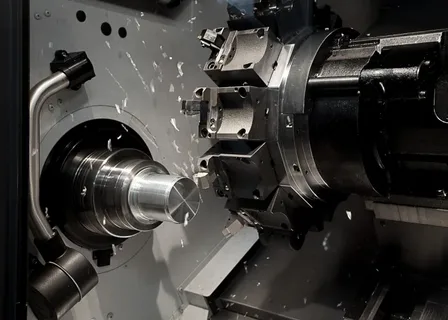

In the ever-evolving landscape of modern manufacturing, CNC turning stands out as a cornerstone process for both prototyping and full-scale production. From precision to efficiency, CNC turning offers a wide array of advantages that streamline product development and help manufacturers stay competitive. Understanding why CNC turning is so vital can offer businesses an edge in today’s fast-paced industrial world.

This article explores the key reasons CNC turning is essential for modern prototyping and production processes. Whether you are launching a new product or scaling up operations, CNC turning is the bridge between concept and reality, offering speed, accuracy, and versatility like no other method.

Precision and Consistency in Manufacturing

One of the most important reasons CNC turning is integral to prototyping and production is its unmatched precision. Traditional turning methods rely heavily on manual input, which can introduce variations between parts. CNC turning, on the other hand, uses computer-controlled systems to ensure that every component is machined to exact specifications. This high level of accuracy is especially crucial during prototyping, where tight tolerances and correct dimensions can mean the difference between success and failure in testing and development.

Moreover, CNC turning machines can replicate the same design hundreds or even thousands of times with minimal deviation. This consistency is critical in production environments where uniformity in every unit is non-negotiable. The capability to produce consistent, high-quality parts ensures reduced waste, lower defect rates, and better overall performance, helping businesses save time and money in the long term.

Rapid Prototyping and Faster Time-to-Market

CNC turning significantly accelerates the prototyping process. Because the technology is computer-driven, once a digital design is created, the CNC turning machine can begin shaping the material within minutes. This rapid conversion from digital model to physical part enables designers and engineers to iterate quickly, test different designs, and make necessary adjustments without waiting for long tooling or setup times, which is often a bottleneck in traditional methods.

For startups and companies in fast-moving industries like aerospace, automotive, and medical devices, getting to market quickly can be a major competitive advantage. CNC turning allows for faster prototype development, which means quicker feedback and refinement. This not only reduces development cycles but also empowers companies to respond to market demands, customer feedback, or technological advancements with agility and confidence.

Material Versatility and Complex Geometry

Another compelling advantage of CNC turning is its ability to work with a wide variety of materials, including metals (such as aluminum, steel, titanium), plastics, and composites. This flexibility makes CNC turning an ideal choice for prototyping and production across various industries, each with different material requirements based on strength, durability, weight, and cost. Whether you’re designing lightweight drone components or robust automotive shafts, CNC turning has the capability to meet the challenge.

In addition to handling diverse materials, CNC turning excels at producing intricate shapes and geometries that would be difficult, if not impossible, to achieve with manual machining. Advanced tool paths and multi-axis machining allow for features like threads, grooves, tapers, and contours with a high degree of precision. This capacity for complex geometry is vital in both prototyping, where unique shapes are tested, and in production, where detailed features must be repeated reliably.

Scalability from Single Part to Mass Production

CNC turning offers exceptional scalability, making it suitable for all phases of product development. During prototyping, the ability to produce one-off or small batch parts is essential for design validation and testing. CNC turning shines here because it requires minimal setup changes and no custom tooling, which reduces both cost and lead time. Once the prototype is validated, scaling up to larger production volumes is seamless since the same CNC program can be used to manufacture thousands of identical parts.

This scalability ensures continuity and efficiency, as the transition from prototyping to production doesn’t require re-engineering the process. It also makes CNC turning a cost-effective solution, reducing duplication of effort and minimizing production delays. Manufacturers can also adjust production runs dynamically in response to market demand, making CNC turning a key asset in agile manufacturing strategies.

Cost-Effectiveness and Waste Reduction

CNC turning contributes significantly to cost savings throughout both prototyping and production stages. Its high level of automation reduces labor costs by minimizing manual input, while precision machining lowers the risk of errors and rework. By ensuring every part meets exact specifications, CNC turning minimizes the material waste often associated with manual methods, leading to a more sustainable and economical production process.

Additionally, CNC turning machines are highly efficient, running continuously and with minimal downtime, which translates to higher throughput and reduced overhead. The ability to quickly adjust and reprogram machines for different parts also allows manufacturers to avoid the expensive costs of tooling changes and setup time. Overall, CNC turning delivers a high return on investment, especially when considering the long-term savings it offers in labor, materials, and time.

Conclusion

CNC turning is more than just a machining process—it’s a foundational technology that supports modern manufacturing from the earliest stages of prototyping to high-volume production. Its advantages in precision, speed, versatility, scalability, and cost-effectiveness make it indispensable for manufacturers aiming to innovate and remain competitive. As demand for faster product development and higher quality continues to grow, CNC turning will remain a critical tool in shaping the future of manufacturing.

Whether you’re developing a new prototype or scaling up for production, investing in CNC turning can streamline operations, improve product quality, and drive long-term success. By leveraging this powerful technology, companies can bring ideas to life faster and more efficiently than ever before.