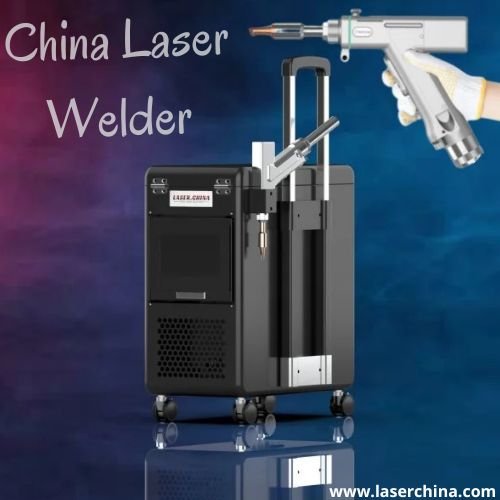

When we talk about welding technology, most minds immediately go to traditional arc welding or perhaps MIG and TIG methods. However, a quiet revolution has been sweeping through the industry, and at its center stands a modern marvel: the China Laser Welder. It’s not just another machine; it’s a game-changer for businesses ranging from automotive to jewelry and even microelectronics. But what exactly is driving this trend, and why are manufacturers, engineers, and artisans across the globe gravitating toward Chinese-made laser welders?

The answer lies in more than just affordability or performance. It’s about technological precision, manufacturing versatility, and a long-standing commitment from Chinese manufacturers to evolve and exceed industry standards. Let’s dive into what makes the China Laser Welder an irreplaceable tool in today’s industrial world.

The Rise of Laser Welding in China

China’s journey into laser technology didn’t happen overnight. For years, the country has been investing heavily in research and development across multiple high-tech sectors. From aerospace to robotics, this push has resulted in significant advancements — and welding is no exception.

Laser welding, a method that uses a high-powered laser beam to fuse materials, is increasingly replacing conventional techniques. Chinese companies quickly noticed the global shift and responded by producing laser welders that meet the demanding needs of modern industries.

Today, China Laser Welder solutions are not only abundant but highly competitive in both quality and performance. Numerous manufacturers, particularly in tech hubs like Shenzhen and Wuhan, have positioned themselves as leaders in this field, offering machines that rival — and in some cases outperform — their Western counterparts.

Innovation Through Intensity

Laser welding operates on a simple principle: direct a concentrated laser beam onto the materials to be joined, and their surfaces will melt and fuse under the intensity. What sets the China Laser Welder apart is the level of refinement in beam quality, control precision, and adaptability across materials.

You can find welders tailored for delicate gold and silver jewelry, as well as heavy-duty models capable of joining stainless steel or aluminum alloys used in construction and automotive fabrication. This flexibility is not just impressive — it’s strategic. Chinese manufacturers understand the diverse applications and are crafting machines that offer solutions across multiple industries.

Moreover, the ability to handle fine and complex welding patterns is something that artisans and engineers alike praise. Precision is the new gold standard, and China Laser Welder models are proving to be priceless in this regard.

Manufacturing Efficiency: A Competitive Edge

What sets Chinese laser welders apart is not just their technological capability, but the manner in which they’re produced. China’s manufacturing ecosystem is unlike any other. With vertically integrated supply chains, an abundance of skilled labor, and access to rare materials and cutting-edge components, China-based companies are able to offer state-of-the-art welders at scale — and with rapid customization.

This means that whether you’re looking for a handheld portable model or a large industrial robot-assisted welding system, you’ll find a China Laser Welder that’s designed with both speed and specificity in mind.

It’s also worth mentioning the importance of support and training. Reputable Chinese manufacturers typically offer comprehensive training packages, detailed user manuals, and remote support. This holistic approach to customer satisfaction is one of the lesser-discussed but critically valuable aspects of choosing a China-based supplier.

Real-World Applications

You might wonder — where are these machines actually being used?

In fact, you’ll find China Laser Welder units across multiple high-demand sectors. In the automotive industry, manufacturers are using laser welding to assemble lightweight frames, battery packs for electric vehicles, and precision parts for engines and braking systems.

In aerospace, where even microscopic faults can lead to catastrophic failures, the precision and reliability of laser welders are indispensable.

The electronics industry also benefits greatly. Think about smartphones, tablets, or even microchips — these gadgets require minuscule yet robust welds that only laser-based systems can achieve efficiently.

Even jewelry makers and artisans are now investing in small-scale China Laser Welders to achieve seamless joints in precious metals without compromising aesthetics. This is a revolution for creative industries that value both beauty and durability.

Global Demand, Local Supply

An important reason why China remains a powerhouse in the laser welding space is the global market’s demand for high-performance, low-maintenance, and cost-effective tools. Many buyers, from small workshops to large multinational corporations, are turning to Chinese manufacturers not only because of the lower cost but also due to the reliability and continued innovation.

E-commerce platforms and B2B marketplaces have made access to China Laser Welder suppliers easier than ever. With multiple models available for same-day shipping or custom build-to-order solutions, businesses no longer face the long wait times that used to plague international procurement.

And let’s not overlook certifications. Many China-made welders now come with CE, FDA, and ISO certifications, making them compliant with international safety and operational standards — a crucial factor for businesses operating across borders.

Breaking the Stigma

There was a time when “Made in China” was wrongly associated with lower quality. That narrative has dramatically shifted, especially in the laser technology sector. Companies like Han’s Laser, GWEIKE, HSG, and MAX are gaining recognition worldwide for producing top-tier machinery.

In fact, several major Western brands are now sourcing components from or fully manufacturing their welders in China. It’s a quiet acknowledgment of China’s prowess in this field — and one that savvy business owners are taking advantage of.

So, when someone asks, “Can I trust a China Laser Welder to meet professional demands?” — the real question should be, “Can I afford not to?”

The Investment Perspective

Let’s talk numbers. Investing in a China Laser Welder often yields high ROI due to its longevity, minimal maintenance needs, and the ability to handle high-throughput operations. Unlike conventional welders that need constant upkeep and part replacements, laser welders have fewer consumables and operate with greater consistency.

The cost range is wide — from a few thousand dollars for compact models to over fifty thousand for industrial-grade systems. However, this cost is typically offset within months, especially in high-volume environments. Add to that the availability of leasing options and local distribution centers, and it’s clear why these machines are turning heads in financial departments, too.

Final Thoughts

In an industry where precision, speed, and adaptability are everything, the China Laser Welder has emerged as an essential tool rather than an optional luxury. With decades of research, unmatched manufacturing capabilities, and a clear focus on innovation, China’s contribution to the laser welding space is not only significant — it’s transformative.

Whether you’re a large-scale manufacturer, a mid-size operation, or a creative professional seeking reliable welding performance, exploring the range of China Laser Welders could be one of the smartest moves you make this year. It’s not just about joining metals; it’s about welding the future with precision, one beam at a time.