Epoxy floors has grow to be an increasingly popular preference for residential, commercial, and commercial spaces—in particular garages—way to its durability, smooth look, and resistance to chemical substances and moisture. However, making use of epoxy isn’t as simple as painting a wall. To gain that smooth, professional-looking finish, having the proper tools is important. One tool that stands proud above the rest is the epoxy go with the flow curler cover.

In this post, we’ll dive into what an epoxy glide roller cover is, why it’s critical on your epoxy projects, the way it compares to different rollers, and the way to pick the proper one to your storage floor or any other floor. Whether you’re a DIY enthusiast or a professional contractor, this manual will assist you understand why this specialised roller makes a tremendous distinction.

What Is an Epoxy Glide Roller Cover?

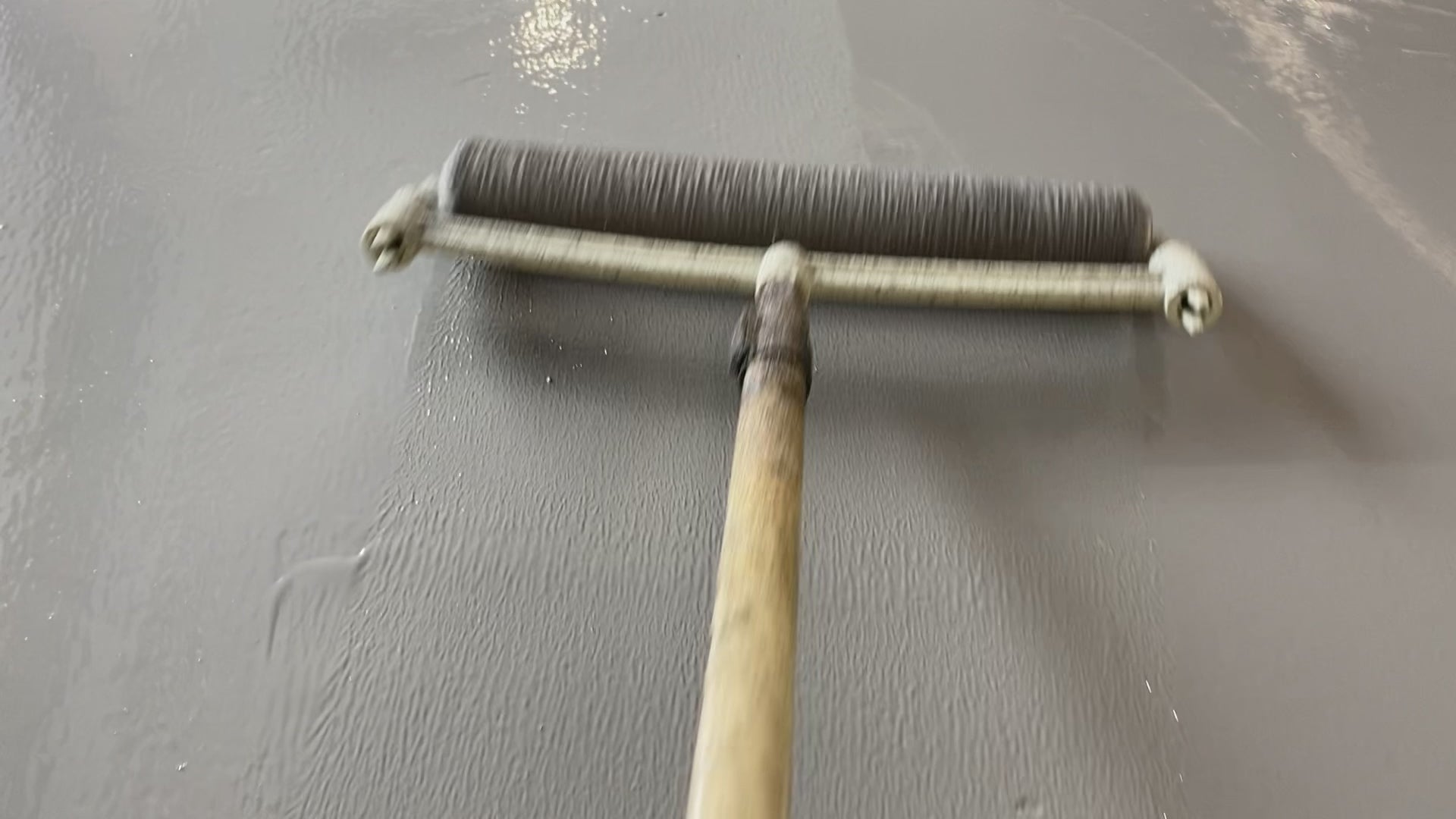

An epoxy float roller cowl is a specifically designed curler cowl supposed for making use of epoxy coatings. Unlike preferred paint roller covers, epoxy go with the flow rollers are constructed to handle the unique viscosity and putting characteristics of epoxy resin. They permit for easy application, minimum effervescent, or even coverage—key elements while working with epoxy materials.

Typically fabricated from lint-loose, woven substances, those rollers save you shedding for the duration of software, which is critical for attaining a easy finish. They are proof against solvents and designed to hold their structural integrity whilst exposed to thick epoxy coatings.

Why You Should Use an Epoxy Glide Roller Cover

Let’s face it: epoxy isn’t cheap, and neither is a while. If you take the time and spending the money to coat a floor with epoxy, you want it executed proper the primary time. Here’s why an epoxy glide roller cowl is a sensible investment:

1. Minimizes Bubbles and Streaks

-

Air bubbles are one of the most common issues in epoxy flooring.

-

A conventional roller can lure air and reason bubbles for the duration of utility.

-

An epoxy glide curler cover, however, is especially designed to lessen this trouble, bearing in mind a clean, even surface.

2. Lint-Free Application

-

Standard roller covers often go away behind lint or fibers, that could spoil the wonderful, sleek look of an epoxy floor.

-

Epoxy glide rollers are normally made with lint-unfastened substances to maintain the floor smooth and expert.

3. Chemical Resistance

-

Epoxy is a robust fabric that can degrade or ruin down the fibers of normal rollers.

-

Epoxy flow roller covers are resistant to the chemical compounds in epoxy, meaning they won’t dissolve, deform, or go away debris in the coating.

4. Uniform Epoxy Distribution

-

These rollers are engineered to keep and release the proper quantity of epoxy calmly.

-

This ensures uniform thickness throughout the surface and enables keep away from skinny spots or puddling.

Ideal Uses for an Epoxy Glide Roller Cover

While epoxy float rollers are maximum normally used for garage flooring, their programs are some distance-attaining. Here are a few best projects:

-

Garage Floors

-

Basement Floors

-

Commercial and Industrial Spaces

-

Warehouse Flooring

-

Kitchen and Utility Room Surfaces

-

Concrete Countertops

No depend the placing, the usage of the correct roller ensures your epoxy adheres well and appears terrific for future years.

How to Use an Epoxy Glide Roller Cover

Using an epoxy go with the flow roller in all fairness straightforward, however there are a few quality practices to make sure premiere outcomes:

1. Prepare the Surface

-

Clean and degrease the floor, then etch or grind the floor to create a profile for the epoxy to adhere to.

2. Mix the Epoxy Properly

-

Follow the producer’s commands for blending resin and hardener.

-

Incorrect ratios can lead to curing troubles.

3. Prime the Surface (Optional but Recommended)

-

Use a primer coat to enhance adhesion and reduce the hazard of bubbles within the topcoat.

4. Load the Roller Evenly

-

Dip the epoxy glide curler right into a paint tray or curler screen.

-

Roll it a few instances to lightly distribute the epoxy on the curler.

5. Apply in Sections

-

Work in conceivable sections, the use of a “W” pattern to unfold the epoxy frivolously.

-

Avoid urgent too hard; allow the curler do the paintings.

6. Backroll for Smoothness

-

After applying, cross over the phase gently again with the roller to even out the coating and get rid of bubbles.

Choosing the Right Epoxy Glide Roller Cover

When selecting a roller cowl on your epoxy task, bear in mind these elements:

Nap Size

-

3/8” Nap: Ideal for clean surfaces, presenting brilliant manage or even spread.

-

1/2” Nap: Better for barely textured surfaces or while a heavier software is needed.

-

3/4” or Higher: Used for rough or porous surfaces.

Width

-

9-Inch Rollers: The general size for most packages.

-

18-Inch Rollers: Great for protecting large regions fast, particularly useful in commercial spaces.

Material

-

Look for curler covers categorized as “lint-loose,” “woven,” and “solvent-resistant.”

-

These features are critical for epoxy software.

Epoxy Glide Roller Cover vs. Standard Paint Roller

Some humans marvel if they can save money by the usage of a regular paint curler. While it is able to seem like a value-saving shortcut, the truth is quite the other.

Here’s a brief evaluation:

| Feature | Epoxy Glide Roller Cover | Standard Paint Roller |

|---|---|---|

| Lint-Free Application | Yes | No |

| Chemical Resistance | High | Low |

| Minimizes Air Bubbles | Yes | No |

| Designed for Epoxy | Yes | No |

| Smooth Finish | Consistent | Risk of Imperfections |

In short, the usage of a general roller can lead to a subpar result that might require steeply-priced remodel. The epoxy drift roller cover is in particular engineered that will help you succeed on the first try.

Maintaining Your Roller Cover

Epoxy roller covers are typically considered single-use items due to the issue of cleaning them after the epoxy has cured. However, in case you’re working on a multi-day challenge and need to reuse your roller, wrap it tightly in plastic wrap or aluminum foil among coats to maintain it from hardening in a single day.

-

Always wear gloves and shielding tools when dealing with epoxy and its associated tools.

-

Proper disposal is likewise vital—check your nearby policies for unsafe cloth disposal hints.

Common Mistakes to Avoid

Using the Wrong Roller

-

Avoid standard rollers now not designed for epoxy.

-

They shed, absorb an excessive amount of resin, and don’t provide a easy finish.

Rushing the Application

-

Take your time and observe a constant pace to make sure even coverage and avoid roller marks or bubbles.

Skipping Surface Prep

-

Proper floor prep is non-negotiable.

-

A poorly prepped ground will result in peeling or poor adhesion.

Not Using a Primer

-

Priming helps create a better bond and reduces bubbling, mainly on porous concrete surfaces.

Final Thoughts

When it involves making use of epoxy, specially on storage floors, the nice of your tools can make or spoil your assignment. The epoxy float curler cover is an essential tool designed to deal with the precise needs of epoxy utility. With its lint-free, solvent-resistant layout, it ensures a smooth, even finish whenever.

Whether you’re resurfacing your house garage, updating a commercial area, or tackling a big business ground, do not cut corners with your tools. Investing inside the right roller makes all the distinction within the outcome, durability, and look of your epoxy coating.

In conclusion:

-

In case you need easy, bubble-free effects and a flawless end that lasts, the use of an epoxy go with the flow curler cover is the smart choice.

-

For everyone asking approximately the best roller for epoxy garage floor, this is it—arms down.